Case Studies

Vision Sensors and Industrial Networks Combine for Industry 4.0 Traceability

In September 2015, the European Parliament issued a briefing paper in which it significantly pointed out that the “ubiquitous use of sensors, the expansion of wireless communication and networks, the deployment of increasingly intelligent robots and machines … has the potential to transform the way goods are manufactured in Europe.” Since that day, industry hasn’t looked back. Industry 4.0 is seen to hold the key to increased flexibility in manufacturing, mass customisation, increased speed, and better quality and improved productivity.

Industry 4.0 embraces a collection of technologies and concepts to create factories where machines in the production process are able to communicate with each other, both internally and externally. This leads to better process optimisation, increased productivity, safety, reliability and flexibility, these will all be highly valued outcomes from successful implementations of Industry 4.0. The revolution will result in a change in the required skill sets for shop floor workers and maintenance staff and it will increase the amount of important predictive maintenance carried out and its accuracy.

Industry 4.0 is set to play an influential role in shaping both the UK and global economy for generations to come. This new generation of technology is unlocking new markets and applications as it works side by side with human workers, increasing labour and total factor productivity and eliminating the need for some employee costs by creating a flexible manufacturing approach.

Across the world, manufacturers are now embracing the vast array of benefits that vision systems can deliver to the factory floor. In turn, they are combining these with major factor information system networks to create ‘big data’ throughout the factory environment. This paves the way for further revolution, and indeed evolution, in Industry 4.0.

What benefits does it bring to production?

For industrial applications, the precise placement of a sensor or control points in Industry 4.0 is critical. Wireless technology offers the promise of no-wires communication, but if you need to power a wireless node by plugging it in, or recharge it every few hours or even months, the cost and impracticality of deployment become prohibitive. For example, adding sensors to rotating equipment to monitor conditions while the equipment is in service is not possible with wires, but the knowledge gained from in-service monitoring can allow customers to predicatively maintain this critical equipment, thereby avoiding unwanted and expensive downtime.

Vision systems help create the foundations for these new flexible factories. Typical projects include the integration of cameras into new production lines, combining vision systems with ancillary equipment such as conveyors for product rejection, pick and place, robotics or the provision of stand-alone inspections, separate to the process, as well as full track and trace of products through a flexible cells. This requires expertise in fields as diverse as mechanical design, mechanical handling and transport systems, software, electronics, robotics, control systems and factory networks.

The combination of vision systems and system networks gives added peace of mind to manufacturers in that it provides full traceability across the factory for serial number tracking. This of course aids quality control meaning they can pinpoint packaging faults, label checks, date inspection and rouge defect detection, all at high speed at any position in the factory. As a result, this give the manufacturer much needed peace of mind.

This operates by placing vision systems onto the network and situating them at various critical points throughout the factory. This then allows for immediate feedback to the engineering managers and factory controllers, who are working side by side with factory information systems and flexible MRP systems. Combining the ability to trace products throughout their life-cycle on the factory floor with unique device identifier (UDI), means the necessary quality control procedures are in place to trace individual product. Sensor-based connected devices and solutions lie at the heart of many applications.

Historically, individual products wouldn’t be tracked via an individual serial number. That has now changed, even in the most diverse industry sectors. For example, from strawberry punnets in the food industry through to pipe fittings in the plumbing industry – single products are carefully monitored and inspected. Manufacturers can gather enhanced data whilst getting real-time control via the networked camera and serial number tracking systems thus improving their productivity, their bottom-line, and general business performance.

Industry 4.0 requires more flexible manufacturing lines and systems such as these are helping it achieve that. It is often the case that automation is behind the scenes and “just works”, without being obvious. The resulting improvements in quality, throughput or efficiency can be startling, but the small boxes with flashing LEDs that make it all happen are often hidden away in enclosures. Wireless and internet technologies will link machines, products, systems, and people, both within the manufacturing plant, and with suppliers and distributors. As a result, we shall see greater flexibility and smaller batch runs, rapid design and prototyping with increased customer involvement, real time error detection and correction, predictive maintenance, and ‘lights out’ factories where automated robots continue production without light or heat – indeed this might see a reversal of the practice of exporting jobs to low labour cost countries.

Case study

The Food and Drug Administration (FDA) in the US released a final ruling requiring that most medical devices distributed in the United States must carry a unique device identifier (UDI). With the directive now started it has become increasingly important for device manufacturers of all industries to put the necessary quality control procedures in place now to confirm the UDI is both legible and traceable. As the FDA sees it, “A unique device identifier system has the potential to improve the quality of information in medical device adverse event reports, which will help the FDA identify product problems more quickly, better target recalls, and improve patient safety.” The UDI allows the device or product to be traced back to its roots in manufacturing.

This directive has implications for any electrical manufacturer but at a fundamental level during the production of the device or product the UDI needs to be applied and quality checked to confirm it meets the necessary specification.

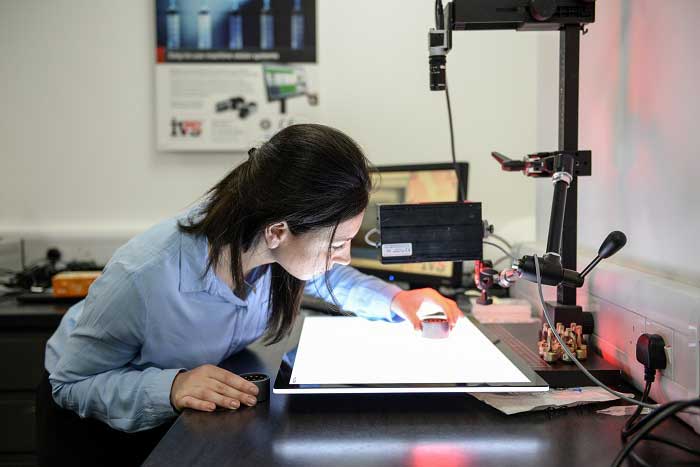

Industrial Vision Systems has been working with a number of companies to tackle these problems through the use of ever more sophisticated automated machine vision systems and processes. So when a UK medical manufacturer recently decided to automate the inspection of its part labels, it turned to engineers at IVS to build an automated label inspection system specifically for the purpose, including full validation to GAMP5 (Good Automated Manufacturing Practice) pharmaceutical regulations.

The system designed at IVS consisted of two digital vision systems viewing two areas of the label, housed in a custom designed stainless-steel housings mounted in front of the label printing equipment. The vision system communicated with the line PLC, printer and factory information system to receive and confirm the relevant part codes and lot codes matched each other and were printed in a legible format. The labels were indexed every second for inspection prior to being applied to boxes housing various medical devices.

The FDA demands that automatic identification and data capture (AIDC) technology is used for the inspection process so the inspection process was imperative for the quality leaving the customers’ factory. By combining Optical Character Recognition/Optical Character Verification with print quality inspection and ID/code reading, the labels were checked in real time through the whole production cycle to confirm compliance to the FDA specifications. Typically, a UDI can be applied to labels, boxes, products, components and devices – therefore a generic approach to the quality inspection had to be constructed. The UDI directive also states that all devices that will be implanted or sterilised must have permanent marks so any vision inspection system must cope with confirming marks on varying material types, including implants. Typically, a code would be applied to include both a human readable and a machine readable mark, be it a 1D or 2D/Data Matrix code. Both need to be inspected to confirm they reach the necessary quality standards. For symbols, this is according to the ISO standards 15415 and 15416. Digital cameras are used throughout the production process connected to a central IVS vision system which then communicates to the Factory Information System database to provide historical information and conformance. Full track and trace is now seen as the ideal solution. Most medical device companies run varied quality systems, data management and IT applications for their UDI requirements. The flexible user interface allows data storage, image storage and historical statistical process control (SPC) data to be easily managed independent of the background IT infrastructure. These latest generation vision systems provide full audit logging and traceability to allow systems to be validated to Good Automated Manufacturing Practice (GAMP) standards. The UDI quality can be tracked through the process to make sure that it has not degraded through the production cycle and that multiple elements (e.g. inserts and instructions) have gone together correctly. The UDI program will provide consumers with a better-quality product, increased traceability against forgery and assurance that the product has been through the necessary production cycle and checks. In addition, the UDI program offers improvements across other industry sectors, most importantly to the food and beverage industry, where date strings, price strings and livery quality are increasingly inspected in real time due to supermarkets every increasing stricter requirements and government guidelines