Image Archiving

Our image capture and archiving vision systems monitor and record your production process 24 hours a day, seven days a week. There is no limit to the number of cameras that may be connected to the system. Images and statistics are provided in an easy-to-understand format, allowing you to swiftly email your customer with all pertinent information in the event of a query.

Machine Vision Applications

Image Archiving

Save a record of every product before delivery thanks to our stunning ultra HD photos with exact colour rendition. It’s the equivalent of having a professional photographer on call 24 hours a day, 365 days a year to capture every product you make.

Never again leave a claim to chance. Photographic evidence allows you to ensure quality while the product is being manufactured or before it leaves your business.

Our systems can store data for many years, allowing you to keep track of every product that leaves your facility for years to come. Your engineers can handle warranty claims swiftly and efficiently.

Advanced Image Archiving

Typical Image Archiving Vision System Applications

- Imaging a complete automotive assembly

- Chassis image archiving

- Saving images of an automotive engine assembly

- Package and box contents

- Storing images of products based on a data matrix code or batch number

- Saving images of parts into sub-folders, e.g. date, time, batch, product code, etc

Capture Your Entire Production

Image Archiving Vision Systems

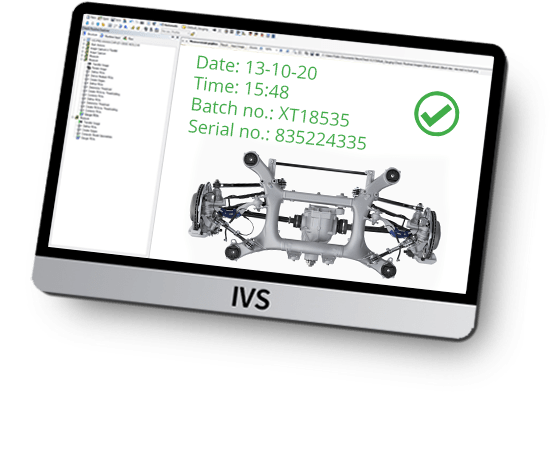

Manufacturers are increasingly relying on vision technologies to archive images during the manufacturing process. In the modern production line, having a simple image record archive of every product manufactured, tagged with the serial number, date, time, and batch number, is now a useful tool.

IVS offers multi-camera image archiving and recording vision systems that capture all aspects of the manufacturing line at all hours of the day. Images and data may be recalled in the event of quality complaints from customers, giving you peace of mind and information to present to your customers, verifying the state of the products as they left your plant.

Simple and reliable systems designed by experts

Explore some of the key features and benefits of using an IVS system for image archiving

Capture Every Angle of A Product

Every angle of each product can be captured and recorded. Even the largest products are covered 360 degrees. We offer secure, real-time image distribution.

Fully Automated Archiving with 24-Hour Coverage

Our vision systems autonomously archive images around the clock. Ensure your production is safeguarded and contact our experts today

Customised Reporting

For exact recall and warranty protection, save images against part, serial, and lot numbers. Find and recall the specific product that was manufactured at the time.

Multi-Camera Protection

Ensuring Every Detail Is Captured

Capture and record every angle of every product. A single system with up to 30 cameras provides 360-degree coverage for even the largest products. We provide secure image delivery in real-time. From every angle, we see everything, from the smallest components to gigantic mega assemblies. 20 mega-pixel ultra-crisp imaging captures all aspects of your product, allowing operators and technicians to zoom in on specific details. With its intuitive and simple-to-use touch screen and 360-degree image views, inspection is made easier and faster.

24-hour Coverage

Protecting Your Brand From Every Angle

The operation is fully automated. Providing 24-hour image storage even when the lights are turned out. There is no need for the operator to intervene in the capture process. Our user-friendly interface makes retrieving old images simple. Images can be exported to a USB stick or instantly transferred over your factory ethernet. Images may be viewed anytime they are needed thanks to improved and extensive archival management.

Monitor Operator Performance

The Benefits of Image Archiving

Take a look at what’s going on in the production line. IVS systems enable you to collect data on how operators and staff perform. You may demonstrate build quality at each level of your production process by evaluating specific images from specified dates and hours. It combines production scheduling with photo saving to give the highest resolution image quality – leave your automated production running knowing that images of the entire build process are automatically recorded.

More about IVS machine vision image archiving solutions

Quality control is a procedure in manufacturing that assures consumers receive defect-free products and components that match their needs according to the agreed-upon specifications. Customers, consumers, and the end-user may be at danger if the quality is poor. Poor quality and out-of-spec components can lead to recalls. However, major recalls can be avoided by using adequate quality control throughout the production process.

Producing components, subassemblies, products, and parts in large quantities almost always results in a product quality complaint at some stage during the production process. This usually happens when the goods arrive at the customer’s location. Without proof of the product’s true quality at a final inspection, before it leaves the factory, there are no grounds to discuss where the blame lies.

By using image arching solutions, the manufacturer can offer verifiable documentation of what the product looked like before delivery by automatically photographing it in Ultra HD at the last inspection, together with a date and time stamp and serial number recall.