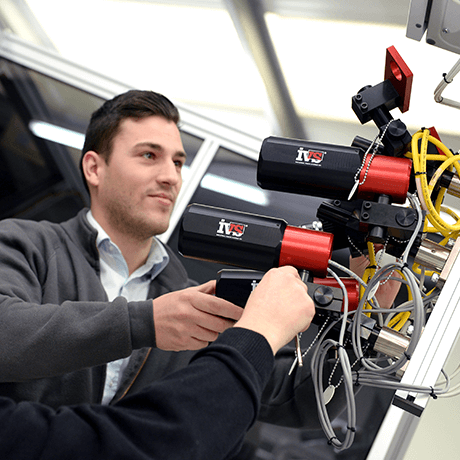

Automotive Catalyst Inspection Machine IVS-CATi

A highly flexible complete inspection cell utilising state-of-the-art robotics and artificial intelligence vision systems combined with servo controlled conveyors for quality control checks on automotive catalyst and associated components.

Our dynamic machine vision systems let you automate repetitive and critical inspection tasks on catalyst parts utilising latest line-scan sensor technology to leverage highly accurate quality control. IVS-CATi uses artificial intelligence vision sensors to provide mission critical quality inspection criteria across the entire production cycle.

With high resolution sensors to provide complete coverage even for larger and metallic products, IVS-CATi inspects with precision detail. Fast throughput conveyors allow quick cycle time inspection and reject for high speed lines.

IVS-CATi is very easy to program, offers fast set up, is highly accurate and provides peace of mind for final quality checks. Leverage our extensive experience in automotive catalyst inspection.

Ideal for automated quality control checking of automotive catalysts

Ceramic and metallic automotive catalysts

Catalyst through hole and blockages

Percentage coverage and yield

Serial number tracking of catalysts

Truck, automobile and smaller parts

Crack and catastrophic failure parts

Oval and round catalyst parts

Rogue parts

Out of spec catalyst components

1D and 2D code reading from catalyst

Features & benefits of our automated catalyst inspection machines

Precision inspection of automobile catalysts

Covers all major catalyst types

Utilises state-of-the-art linescan sensor technology

Full reporting and real time image information

Need expert help & advice?

We offer engineering advice and support for all machine vision applications. Call us on +44 (0) 1865 823322 or enquire below

About IVS

Founded in 2000, IVS is now one of Europe’s leading specialists in inspection machines and artificial intelligence vision products – supplying customers all around the world and building an unrivalled reputation for innovation, quality and precision in machine vision systems for inspection, guidance and identification.