Special Purpose Vision Machines

Complete automation solutions for quality control, vision ID, robot control and product verification.

Custom Vision Inspection Systems,

Cells and Lines Tailored to your

Exact Needs

We design and manufacture leading-edge control inspection machines

that enable high-precision machine vision inspection, verification and analysis

across all industries.

Custom designed to your exact specifications. We utilise state-of-art-design and rendering 3D CAD so you can see exactly what you will be receiving before it’s built.

IVS integrate third-party equipment such as conveyors, robots, sensors, pick & place and automation equipment into our machine designs – improving your efficiency.

Designed and manufactured to all the latest European Directives & Standards. Comprehensive Electrical Testing and SISTEMA report form part of our Technical File.

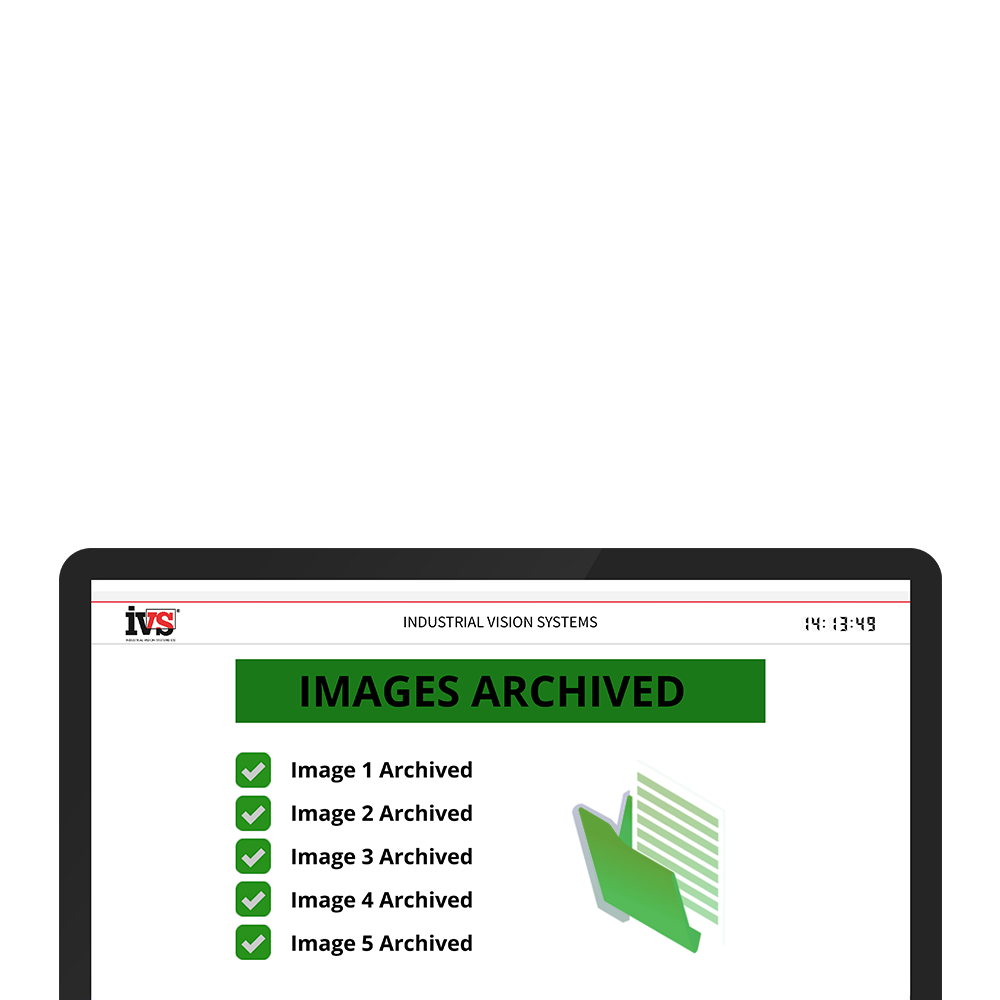

IVS machines integrate directly with all factory information systems, allowing complete part tracking & traceability of image and data saving.

IVS machines are built and tested at our brand new 10,000 sq. ft. production facility at Harwell Campus, under our tough quality management system. Machines undergo vigorous trials before commissioning on-site by IVS engineers. All machines are provided with full CE marking.

IVS is committed to world-class-excellence in product training and support services. Our brand new state-of-the-art facilities providing classroom and application training.

Allow IVS to take care of the management of the vision project, leaving your engineers to get on with their own busy schedules.

IVS is your best in class partner for complex vision system projects and machines that require bespoke 3D CAD design, manufacture, advanced integration, robotics, control or customised development for your production line. Reduce your risk, minimise project lifecycles and increase your productivity.