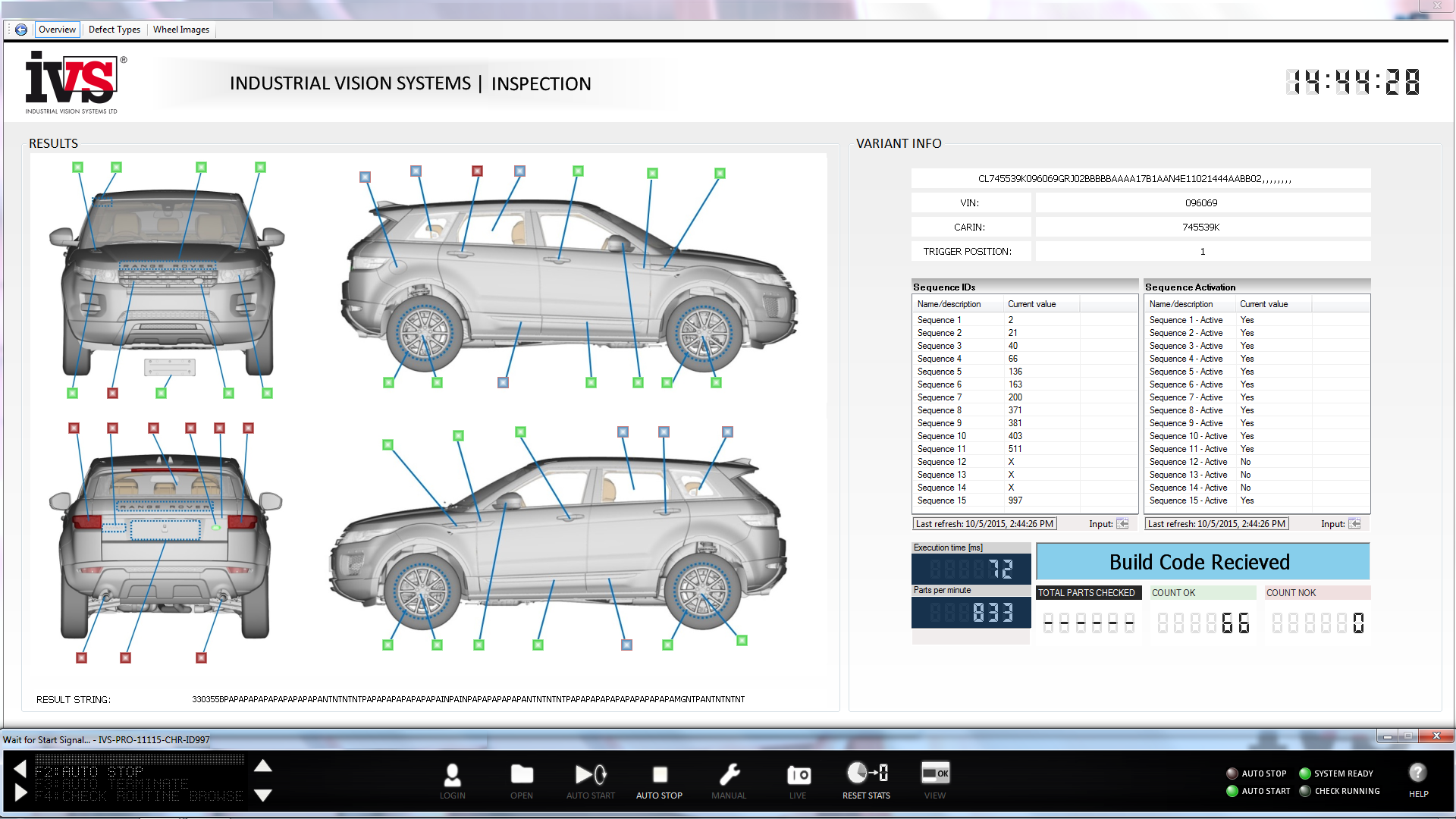

Car Conformance Inspection IVS-ELCi

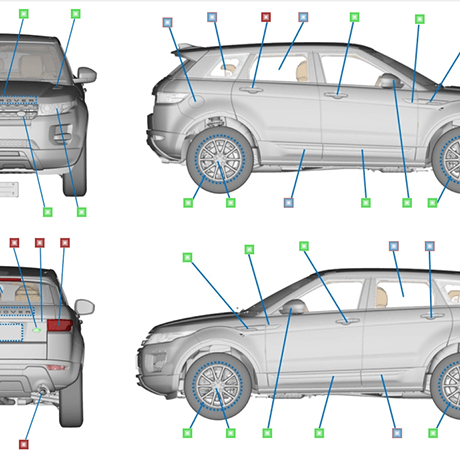

A highly flexible end of line automated car inspection and conformance cell which removes human error in the complete quality check of car body conformance to specification.

The quick to install precision quality control inspection system from Industrial Vision Systems lets you automate repetitive and critical inspection tasks covering the entire vehicle body to check specification to build manifest. Our systems use artificial intelligence vision sensors to provide mission critical quality inspection criteria across the entire vehicle build cycle.

With adaptable vision sensors to provide complete coverage, our car conformance systems inspect even the most mundane tasks, freeing up your employees’ time to add value to other stages of automotive production. Our machine vision systems are very easy to program, offer fast set up, are highly accurate and provide peace of mind in final vehicle acceptance.

Ideal for automated quality control checking of automotive manufacturing

Checks complete car conformance

Vehicle decals, logos and text inspection

Colour matching of components to specification

Exhaust type confirmation

Headlamps and tailights type verification

Wheel type verification

Licence plate variant quality checks

Cladding & trim inspection

Correct paint colour on parts

Legal label requirements – slam panel, pillars, fuel caps

Caps and insert checks

Privacy glass fitted to specification

Type & part verification

Door handles, mirror scalps and trim match

Label type and verification

Features / Benefits

Removes human error from the inspection process

Guarantees final quality leaving the factory

Checks all parts on every side of the car automatically

Frees up operators from mundane and repetitive inspection tasks

Need expert help & advice?

We offer engineering advice and support for all machine vision applications. Call us on +44 (0) 1865 823322 or enquire below

About IVS

Founded in 2000, IVS is now one of Europe’s leading specialists in inspection machines and artificial intelligence vision products – supplying customers all around the world and building an unrivalled reputation for innovation, quality and precision in machine vision systems for inspection, guidance and identification.