Presence Verification

Automated presence verification for factory control, assembly verification, quality inspection and guidance.

Presence Verification Vision Systems

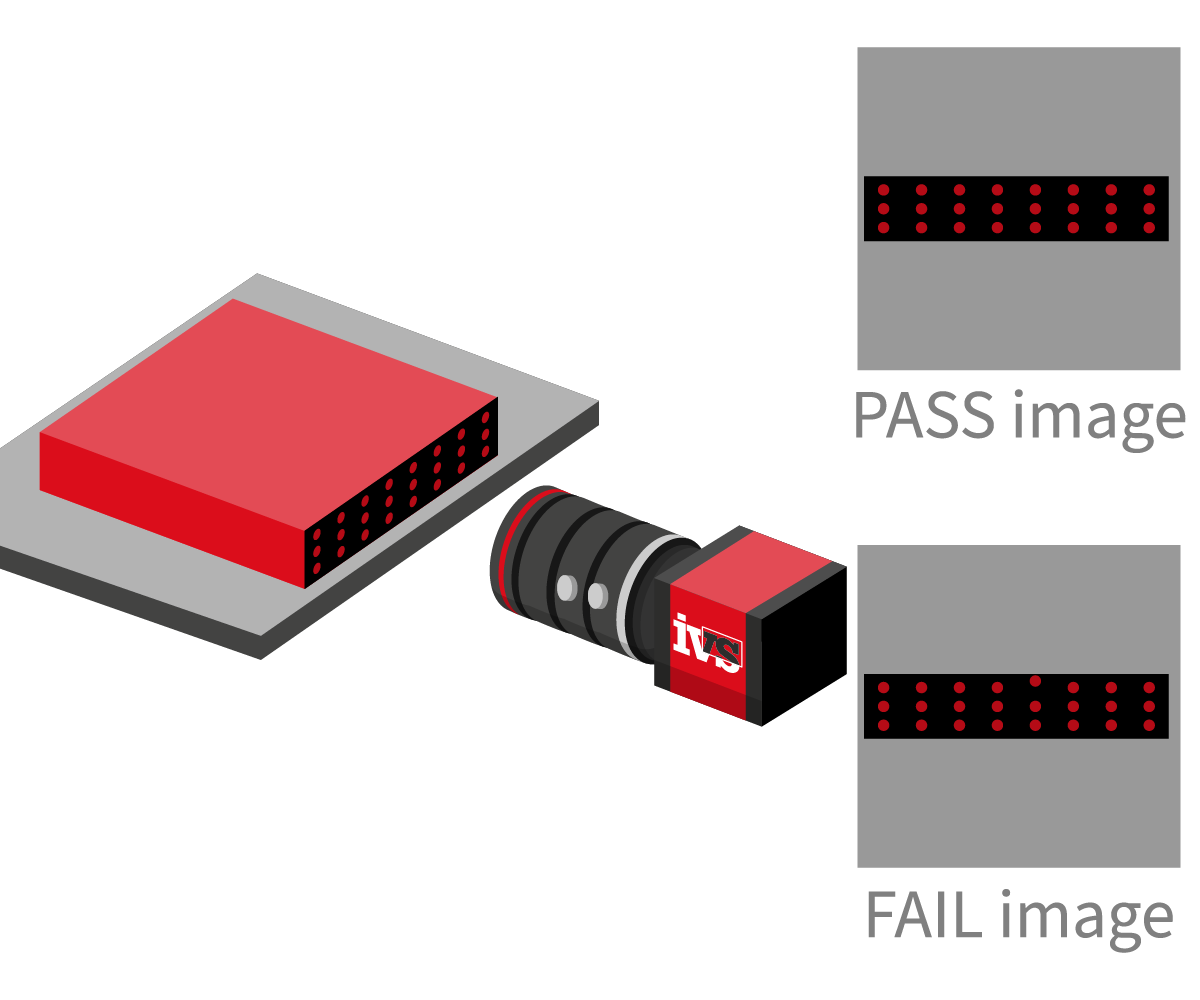

Presence inspection is used to confirm the quantity or the presence/absence of parts or components on a target. There is a considerable variety of presence inspection used in machine vision.

Presence inspection vision solutions by IVS® are used on automated production lines for quality control. Due to increased factory automation, industrial vision systems and image processing technologies have been actively introduced into industrial automation over the last few years. Here we describe the advantages of using vision systems and machine vision for presence verification inspection, combined with the basic principle and practical applications of presence inspection using image processing.

Why you need our presence verification solutions

Discover the benefits of IVS providing your machine vision presence verification applications

Automated Verification

Remove human input and operator reliance. Check components, parts and sub-assemblies using fully automated quality control vision inspection.

Flexible Manufacturing

Produce product faster and more accurately using automated machine vision. Industrial automation using machine vision allows for fully flexible manufacturing.

Save data

Provide your operations and process management with data and statistics on the quality checks completed. Drill down on missing products and bad quality.

Our vision system presence verification applications

Explore some of the key features and benefits of using an IVS vision system for verification, presence, appearance checking

Precision Verification Checks

Use automated machine vision systems for checking the presence and absence of your production. Fully automated quality control.

- Verification of clips, screws, springs, components and parts in place

- Counting components in pallets

- Verifying the presence of products in packages

- Monitoring the appearance of labels, marks, print and seals

- Confirming the presence of electronic components on PCBs

- Proving the existence of screws/washers for securing parts

- Verifying the presence of adhesive beads

- Type verification for Just-In-Time build manufacturing

- Monitoring the occurrence of cuts in material

- Industry 4.0 flexible manufacturing checks

Automated Inspection v Manual Inspection

Presence inspection has depended on visual inspection using human operators for many years. However, this involved the risk of missing failures depending on the physical condition or experience of inspectors, the light in the room or the time of day of inspection. Machine vision has been introduced to reduce human errors and improve work efficiency for inspection tasks involving presence verification.

Manual visual inspection causes variations in accuracy due to individual differences among operators and missed quality criteria. 100% quality inspection requires a large amount of time and effort on the part of the manufacturer. To solve these problems, IVS machine vision has been introduced to replace human eyes for recognising and judging presence targets. In recent years, HD full-colour cameras capable of high-speed transfer have become available, and image processing technology has also seen significant advances. IVS machine vision is now widespread in industrial automation.

The Technology Behind Verification Checking

There are a number of ways the IVS vision system can complete presence verification; these include:

- Threshold-based analysis

- Pattern-based “target” verification using a master template

- Contour-based verification

- Colour image processing

- Ai deep learning algorithms

Threshold-based analysis: Binary processing converts the image represented in greyscale into an image that consists of two levels, black or white. Each pixel is changed into black or white based on a specified threshold level. This is the traditional way of presence verification in machine vision.

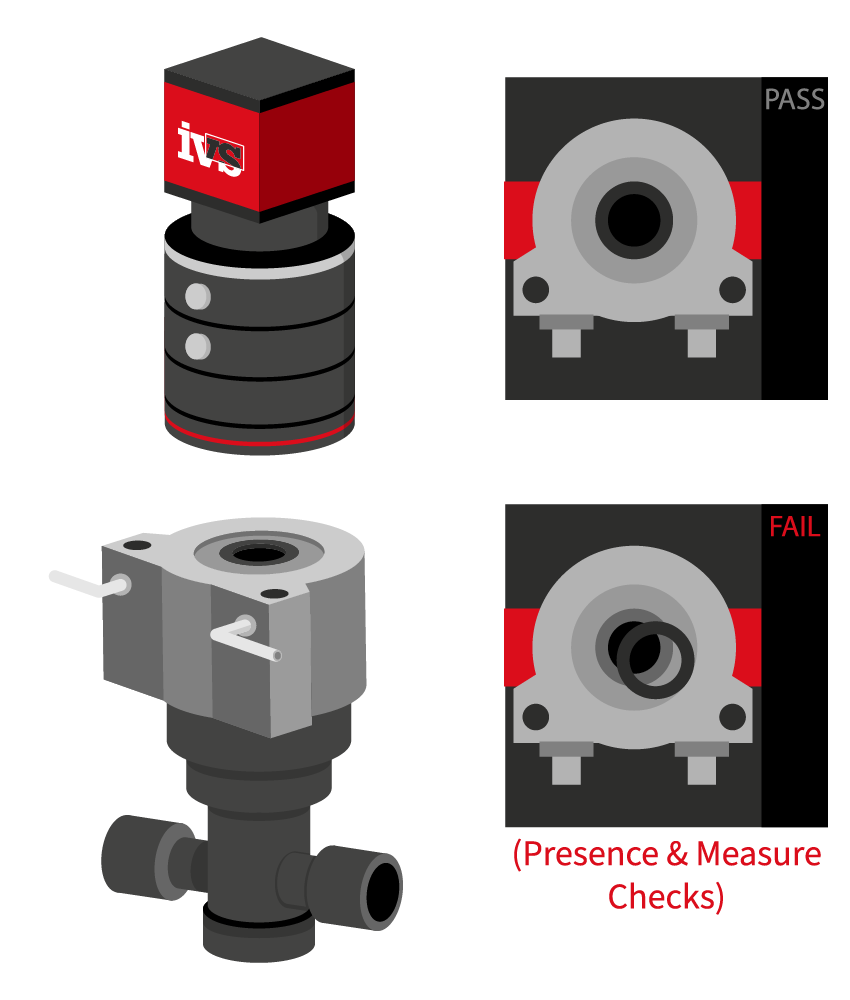

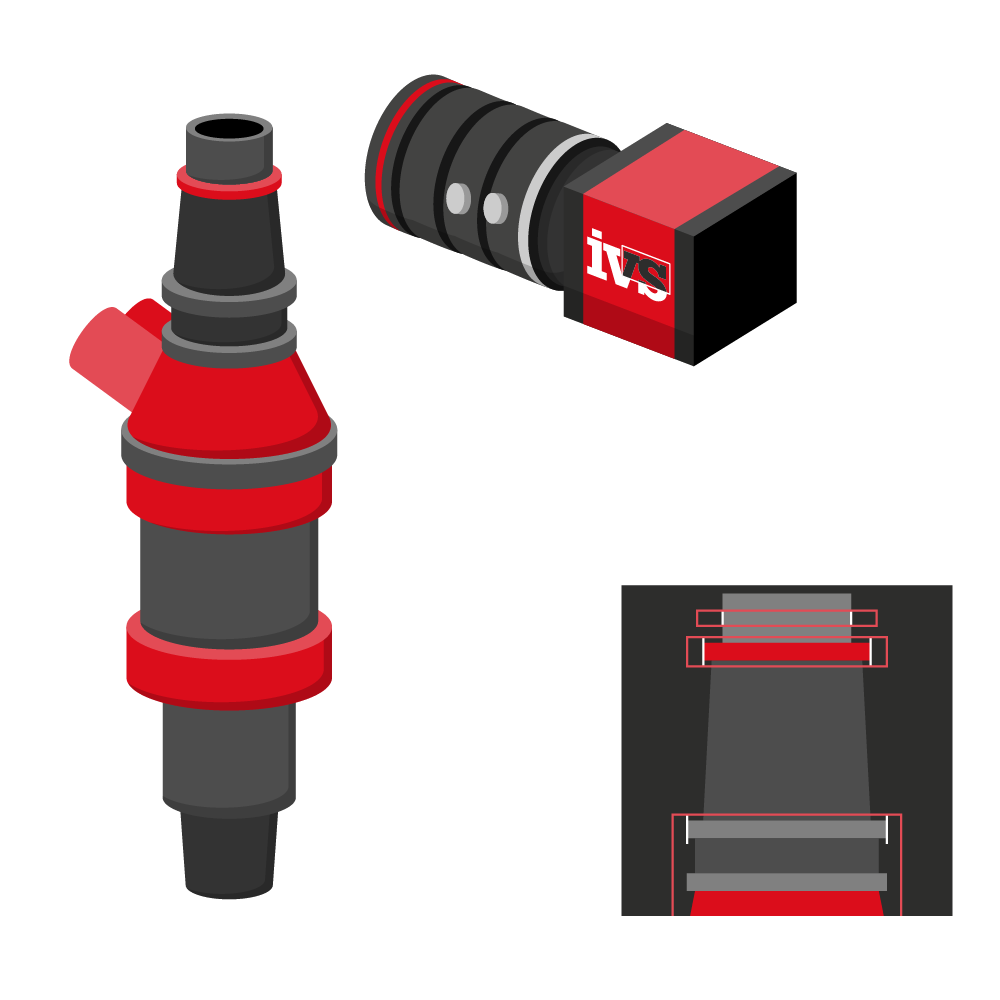

Template matching: A master “template” is trained for the part or component requiring verification. Every image is then compared against the master for matching verification. Contour-based verification: IVS system can use geometric features to find an object. We can quickly and reliably find multiple models that are translated, rotated, and scaled with sub-pixel accuracy. The system locates an object that is partially missing and continues to perform when a scene is subject to uneven changes in illumination, thus reducing lighting requirements.

Colour-based checking: Using 24-bit RGB analysis of an area allows specific coloured components to be easily identified in a scene.

Ai Deep Learning in the context of industrial machine vision teaches robots and machines to do what comes naturally to humans, i.e. to learn by example. New multi-layered “bio-inspired” deep neural networks allow the latest IVS® machine vision solutions to mimic the human brain activity in learning a task, thus allowing vision systems to recognise images, perceive trends and understand subtle changes in images which represent defects.

Fully Automated Vision Control

Fully automated vision control enables IVS customers to deliver a superior and quality product. Vision can be used as part of the manufacturing or packaging line quality control to confirm final products, components or packs are verified as complete and good for sale. Check sub-assemblies are complete and to customer specifications.

To verify parts, assemblies and packaged goods, our vision systems provide high speed, reliable options for checking the presence, size, position, shape and completeness of features. Machine vision systems are also used to check assemblies, sub-assemblies and components are complete and meet customer specifications and to automatically identify defects before parts leave the production line allowing yields to increase and ppm counts to fall.

Interested in Presence Verification Applications?

Get in touch today so we can answer and questions you have regarding our presence verification vision system applications. See how we can save you money, protect your brand and increase your yield using automated vision solutions.

Send us a message and we will respond as soon as possible.

Have a Question? Get in touch

An introduction to presence verification in machine vision.

From the standpoint of the problem at hand, presence verification appears to be easily grasped and structurally rather simple. This is why presence verification is frequently used as a starting point for machine vision and vision system application examples. In reality, the concept of presence verification is difficult to define precisely: is it simply counting objects, or do properties of these objects matter? Are these properties merely characteristics, or does the entire appearance of the object need to be considered? Do properties only apply to individual objects, or do we also need to consider object relationships, such as when performing assembly verification or control?

The methods employed in this field are as diverse as the questions posed above. Methods from other application areas, such as classification and gauging, are frequently used as tools for presence verification. Another reason why presence verification is not always chosen as the starting point for an introduction to image processing and machine vision is that this field is defined more by how questions are asked than by specific methods and algorithms. When using gauging as a tool for assembly verification, it is usually less important to ensure that specific dimensions are within narrow tolerances than it is to ensure that certain relationships between objects are checked. Classification in the context of presence verification is less concerned with what objects are present (which is the ultimate goal of character recognition) and more concerned with whether the correct object is present.

Presence verification problems are typically difficult to approach due to the variety of questions asked and methods used. Solutions to gauging and classification tasks are usually quite similar to one another, as well as to how a human would describe the task intuitively. The fundamental approach to presence verification applications is frequently more difficult to find and less intuitive.

The list below summarises some of the general properties of presence verification problems. Because this application area is so diverse, inspection routines are rarely built on predefined structures. The hardware configurations (illumination, number of cameras, etc.) vary accordingly. Such specialised aspects of the applications described above did not appear to be useful to include in this summary.

Presence verification problems: This is a very heterogeneous application area, ranging from simple object counting to validation of basic features and recognition of objects using classifiers to assembly verification with gauging methods.

Simple presence verification: The validity of the objects to be inspected can usually be checked using simple feature screening in this type of application. This refers to inspecting individual object features using numerical limit values. Following segmentation, basic features such as size, brightness, and so on are computed, invalid objects are removed, and remaining objects are counted. If template matching is used for segmentation, the correlation coefficient is already a first measure of the validity of detected objects.

Assembly verification with gauging: In this type of application, validity of objects follows from gauging results; i.e. in addition to basic features, relationships between objects, e.g. distances, angles, circle similarity, etc. are important. It is usually more important how the measurements relate to reference objects than achieving particularly high accuracy.

Presence verification using deep learning classifiers: If complex interdependencies between features have to be checked to determine the validity of objects, or if the entire appearance of the objects is important, classifiers can be used for object screening which have been trained to distinguish appearance and features of valid and invalid objects.

Contrast-free presence verification: Structured lighting, for example laser lines, can be used to segment relevant objects under conditions where no visual contrast can be achieved—for example in the case that the foreground, i.e. relevant objects, and background are made out of the same material.

Relevant properties: The main challenge in most presence verification tasks is converting the quality criteria into measurable, calculable quantities. For example, the requirement that a filter must not be mounted askew can be checked most reliably by measuring symmetrical distances.