Colour Matching & Verification

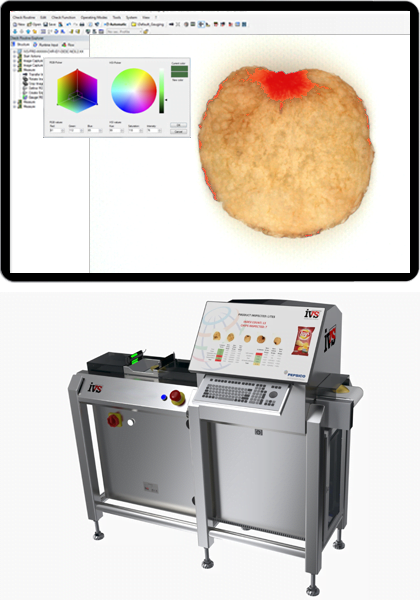

Our powerful vision systems provide colour processing to offer enhanced image processing and precision for quality control applications – everything from inspecting pills, to blister packs or verifying foodstuffs.

Machine Vision Applications

Colour Matching & Verification

Colour matching is the identification of features, products and packaging by their colour.

Precision colour analysis checks can be used to confirm parts meet strict colour band tolerances and to check labels, foreign objects, features, conformal coats, beads and glue.

Advanced Colour Recognition

Typical Colour Matching Vision System Applications

- Inspection of foodstuffs for foreign objects

- Checking labels meet the required colour specification

- Conformance of features

- Inspection of PCB conformal coat

- Verifying beads or glue are present and meet all specifications

- Inspection of food products, organic products and parts

- Sorting of plastic components

- Verification that automotive paint finishes meet strict colour band tolerances

- Presence verification of kit system components

- Inspecting the wire colours in a wire harness

Colour Inspection Opens New Inspection Possibilities

Colour Recognition Vision Systems

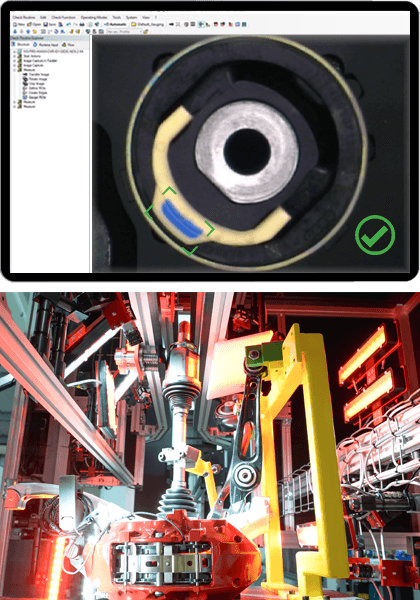

Machine vision colour recognition is used to locate coloured features or parts at high speeds to confirm colour presence, colour band tolerance and form. Colour processing can also be used to mask certain areas from inspection, position other vision tools and enhance image processing. Using the latest high-definition colour sensors, optics, and lighting, as well as a range of advanced inspection methods, our vision systems can reliably find and classify colours even in the harshest of environments.

Simple and reliable systems designed by experts

Explore some of the key features and benefits of using an IVS system for colour matching

Fast Recognition

Our colour processing algorithms recognise colours in fractions of a second, allowing us to give high-quality real-time results.

The Latest Technology

We combine the latest high-resolution colour cameras, optics, lights and filters to detect even the most subtle colour changes.

Remove The Human Element

Humans are inconsistent when classifying colour – our vision systems can compute, isolate and evaluate even the smallest fluctuations within a scene.

Colour Matching Using Machine Vision

Ensuring Colour Conformance

Overall quality verification of parts, components and sub-assemblies can be achieved through colour searching, colour computation and colour matching. Colour processing can be used for segmentation and analysis of products using the RGB, HSI and LAB colour spaces.

Once the colour has been isolated in the scene, measurements of the coloured object, including the overall area of the colour, can be acquired. This can be utilised for a variety of inspections, such as glue thickness, sorting, and wire length checking, etc.

Vast Application Experience

The Technology Behind Machine Vision Colour Matching

There are a variety of ways an IVS vision system can recognise and classify colour, these include:

- Colour Matching

- Colour Computation

- Combining colour channels

Colour matching: for the piece or component that needs to be examined, a master “colour reference model” is taught. Each region of interest is then compared to the master colour to confirm that they are similar or within an acceptable range. Within the scene, several colour models to be found and evaluated.

Colour computation: each pixel can have its associated values computed for RGB, HSI or LAB. Allowing finite limits to be set against minute colour variations.

Combining colour channels: our powerful vision software suite allows us to separate, combine and subtract colour wavelengths, creating enhanced images for superior image processing.

Product Verification

The Benefits of Colour Matching

Colour matching can be used in manufacturing applications to detect the presence or absence of an object based on a reference colour model. Colour tools aid in establishing an appropriate colour match between components within the same product as well as analysing minor colour variations. Colour matching can also be used to accurately locate objects despite variations in angle, size, and shading, and without relying on grey levels.

More about IVS machine vision colour matching solutions

Most industrial vision inspections can be performed with monochrome cameras; nevertheless, there are occasions when we need to employ a colour camera to isolate and analyse regions of interest in a scene that are not discernible with a monochrome camera. Colour cameras open quite a lot of possibilities for image processing, such as merging images from different colour spectrums and isolating single pixels based purely on their colour space values.

By precisely analysing colour across a variety of colour spaces, our colour matching systems can help to eliminate operator error. For accurate colour matching, choosing the right camera, illumination, and optics is critical. Our professional team will work with you from concept to project delivery.

How do you ensure a vision system analyses colour correctly?

Reference colours can be created from “gold master” samples, once the reference colour is stored on the vision system controller, tolerances can be set using our advanced machine vision software.

What colour spaces can be used in machine vision systems?

We can perform analysis of products using the RGB, HSI and LAB colour spaces. Finite tolerances can be set in a number of different ways.