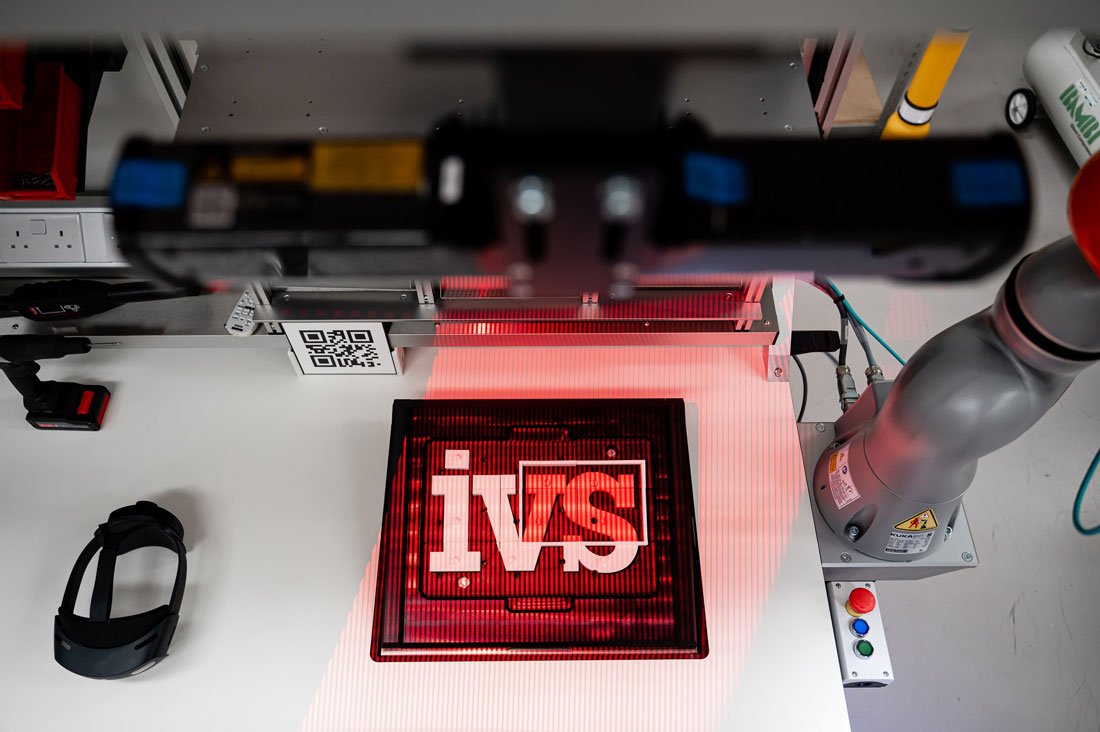

Operator Guidance Platform

User-friendly operator guidance combined with automated vision inspection, augmented reality, smart tools and digital work instructions.

Flexible Production

A single platform for all your manufacturing operations

User-friendly operator guidance systems combined with automated visual inspection. Guide and check every operation. Elevate your workstations into interactive, digital environments – guiding, validating and inspecting every assembly and operation.

Revolutionise your picking and assembly processes with our cutting-edge projected augmented reality (AR) guidance systems. Achieve unparalleled accuracy and efficiency as every operation is meticulously validated through advanced vision inspection technology. Elevate your workflow standards, boost throughput, and ensure precision with ease.

Transform workbenches into intelligent digital workstations

Empowering interactive environments

- Guide operators with AR and vision

- Monitor operator status and yield

- Validate operations as they happen

- Increase quality and lower recalls

- Easy training of temp staff

- Projected step-by-step instructions

- Inspect products as they are made

- Convert manual operations into data information

- Integrate with factory information systems

- Improve operator consistency & reliability

- Optimise manual assembly processes

- Reduce scrap and rework

Industry 5.0 flexible production solutions

Explore some of the key features and benefits of using a IVS intelligent workstations to improve speed & efficiency of production

- Deep Industry Knowledge

Elevate your assembly processes effortlessly using advanced AR guidance, empowering your operators to navigate through intricate tasks with ease. Provide instructions in any language. Allow temporary staff to work without supervision.

- Fast onboarding

Empower your staff with Operator Guidance to ensure smooth knowledge retention and quick onboarding. Digitise, update, and communicate procedures with ease. Reduce training time with live, step-by-step tutorials.

- Paperless work

Store processes electronically in a central area, converting paper manuals into digital work instructions. Augmented reality technology allows for interactive, step-by-step instructions – supporting your clean-desk policies.

Augmented Reality (AR) & Projected Work Instructions

Digital work instructions help guide & train operators with ease

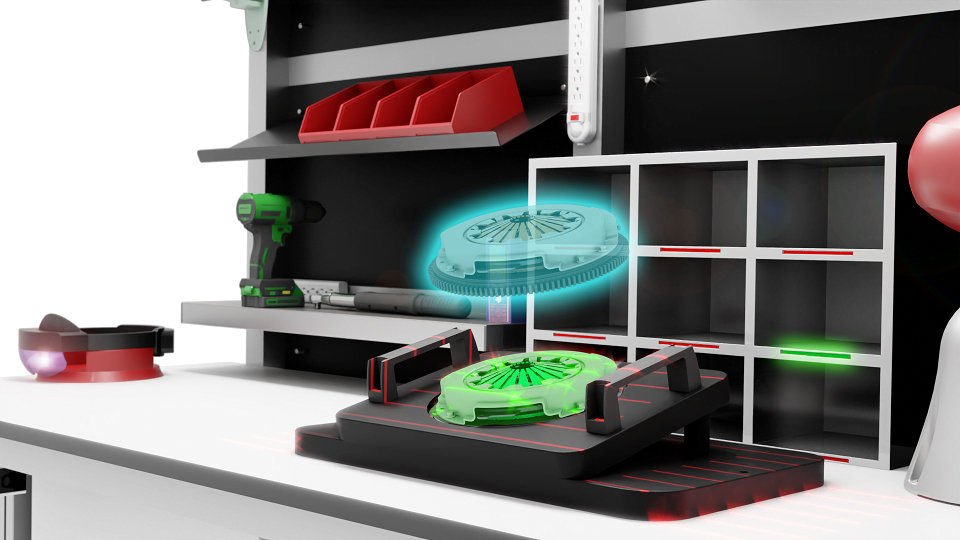

Augmented reality (AR)

Beam instructions to the operator in front of their field of vision, guiding them step by step through complex assembly tasks.

Paperless manufacturing

Create paperless manufacturing and guide workers through any manual process with the aid of digital step-based work instructions. With added projections of CAD and part drawings.

Flexible production

Gear up high-mix-low-volume production processes by transferring the correct information at the right time and providing workers with real-time feedback during process execution.

Build instructions at scale

Augmented Reality (AR) instructions can guide operators and execute quickly, reducing training and operator dependency.

3D Vision System Checks

Confirm operator assembly as it happens through automated vision systems

Automated inspection

Validate product quality and operator assembly as it happens using 3D vision systems, reducing the risk of human errors.

Reduce scrap and rework

Drastically reduce scrap and rework by checking “live” operations on the shop floor. Rework can be completed immediately, increasing production yield.

Real-time data

Improve your factory data by immediately seeing quality trends and spikes in quality. Production managers have a better insight into current drifts and patterns in manufacturing.

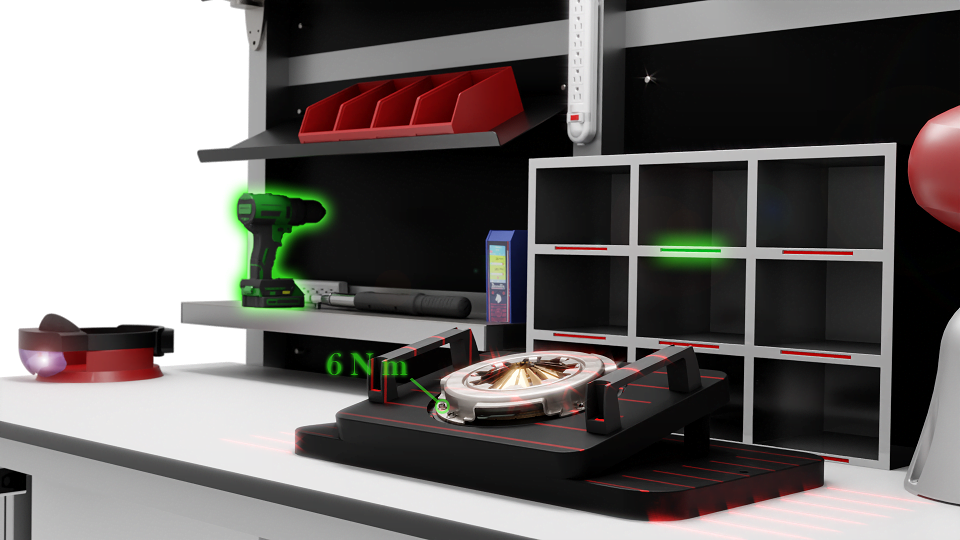

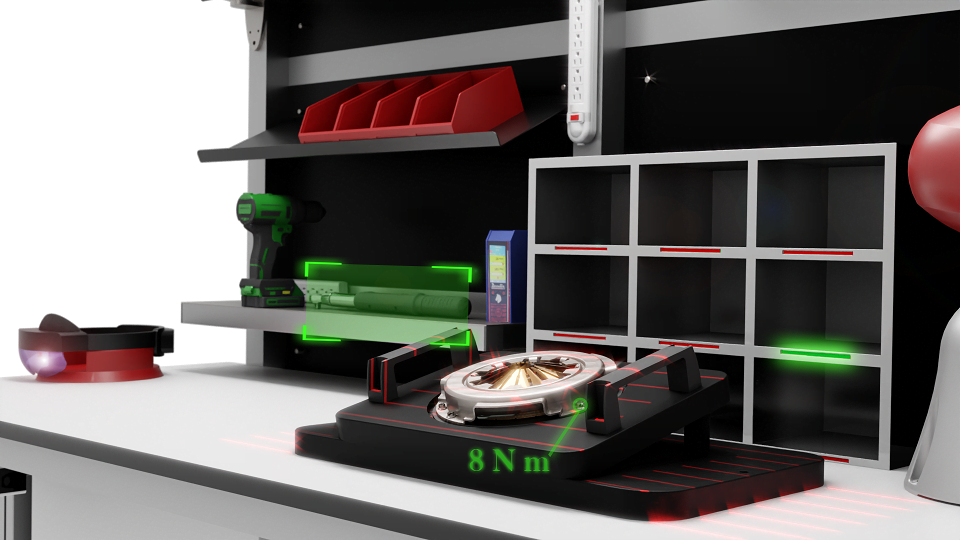

Pick-to-Light & Smart Tools

Guide operators with smart manufacturing.

Pick to light guidance

Coloured projections ease operator reliance combined with AR instructions. Pick the right component at the right time.

Facilitate easy on-boarding

Guide new workers quickly and efficiently, reducing the need for complex training for new staff. Accelerate your onboarding processes.

Smart Tools

Interface smart tooling to allow feedback of operation and torque reached, reducing operator dependency.

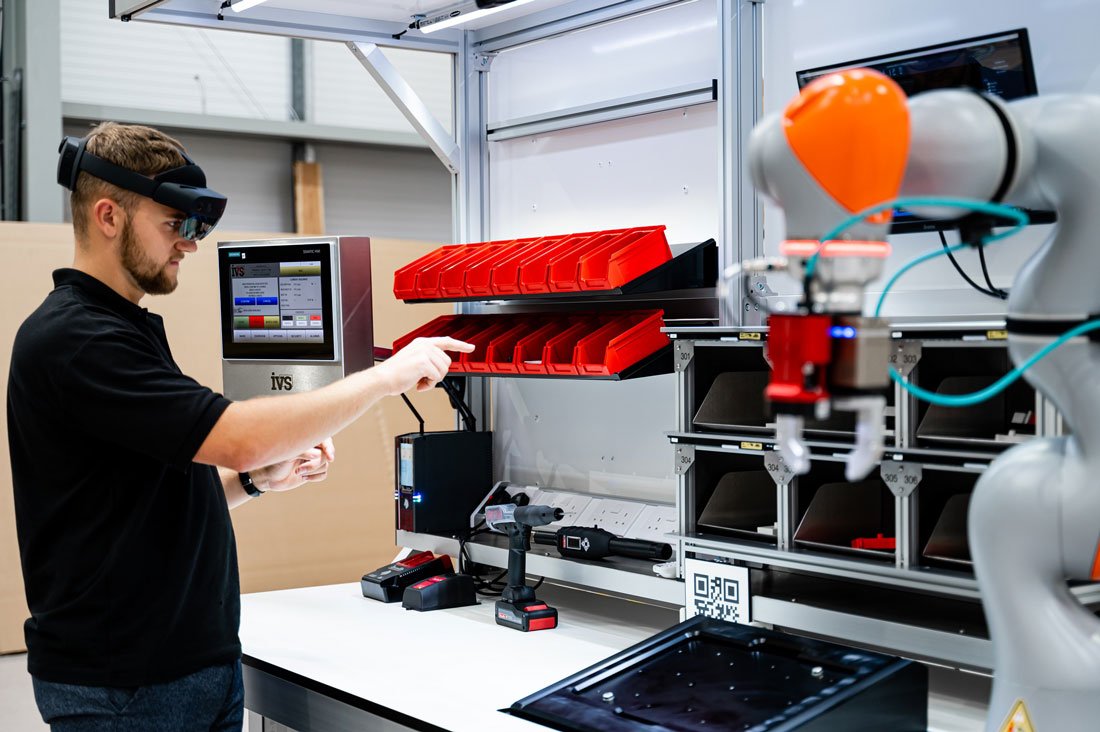

Cobot Workers

Combine operators with robots

Operator help

Cobots operating side-by-side to assist with assembly and packing. Pick and give. Ease handling and reduce operator tasks.

Integrate with AGV

Allows Automated Guided Vehicles (AGV) to interact with the operator guidance platform for continued supply of components.

Reduce expensive tooling

Quickly and precisely locate and align components and products ready for operator assembly.

Interested in Operator Guidance Platform?

Get in touch today so we can answer any questions you have regarding our Operator Guidance Platform and how they can save you money, increase your production speeds and turbo charge your yield.

Send us a message and we will respond as soon as possible.

Have a Question? Get in touch

Augmented Reality Operator Guidance Platform

More about flexible manufacturing

How industry 5.0 flexible factories are the future.

Industry 5.0 refers to robots and smart machines that collaborate with humans while also aiming for resilience and sustainability. Whereas Industry 4.0 concentrated on technologies like the Internet of Things and big data, Industry 5.0 aims to reintroduce human, environmental, and social dimensions. Operator guidance platform are adhering and enhacing the Industry 5.0 philosophy.

Manufacturers all over the world have made significant investments in the automation of their manufacturing facilities. These smart factories are being outfitted with advanced sensors, embedded software, and robotics, as well as gathering and analysing pertinent data to help make better decisions. Despite the ongoing push for further automation, manual workstations and benches remain necessary in most industrial plants. These workstations require a significant overhaul, as present processes are frequently based on outmoded technologies, stifling intended productivity and quality gains.

Breaking down your assembly process into comprehensive working procedures may be simple, but putting those procedures into action on the factory floor is difficult. Operators don’t have time to peruse lengthy instructions because interruptions slow the assembling process. Furthermore, protocols must be kept up to date at all times. Finally, there is no way to check that your operators are following your protocols. By providing your operators with just-in-time digital work instructions via projected AR, instructions can be written in text, image, or video format and displayed exactly when needed throughout the assembly process. Digital work instructions allow you to standardise your assembly process while eliminating printed procedures and manuals. In this manner, you can provide your operators with the necessary support without limiting their independence.

Overall, operator guidance platform allow you to combine all the elements from the factory of tomorrow into a complete operator-centric workstation. Easing workflow, creating flexible manufacturing and integrating quality checking into the point of delivery.