Medical & Pharma Inspection Solutions

Validated quality control vision inspection for the medical device and pharmaceutical industries. Improve quality, reduce your fail rate and guarantee highly efficient production.

Product quality inspection through the entire production chain.

Find and fix manufacturing issues. With our unique vision solutions, we check a wide range of features and properties to safeguard your quality. Flexible and adaptable solutions, validated to GAMP & FDA standards. From incoming parts inspection, component & metrology checks, through to end of line track and trace. Reduce quality escapes that result in unhappy customers.

Automated vision inspection of production and packaging processes in medical device and pharmaceutical production is now a critical quality inspection and quality control requirement.

Why you need our medical device and pharmaceutical vision systems

Discover the benefits of IVS providing your validated vision inspection solutions

FDA & GAMP Approved

Our vision inspection systems are designed from the bottom up for medical device and pharmaceutical compliance. We provide the full validation paperwork, as well as adherence to 21CFR Part 11.

Easy-to-use Vision

We understand your industry, our solutions are ready-made for ease-of-use automated inspection. Our powerful vision interface provides real-time data and statistics so you understand your production.

Versatile Inspection

Our machine vision solutions safeguard your quality, providing a wide range of features and properties. Flexible and adaptable, with everything from precision metrology checks through to product and packaging verification.

Our Medical Device and Pharmaceutical inspection products

Explore some of the key features and benefits of using IVS vision inspection systems for medical, pharma and healthcare production.

Automated Metrology Machines

Enhance your quality processes with our non-contact measurement technologies. Benefit from accelerated metrology by using our automated metrology machines to inspect your products in seconds. Based on our proven platforms, we have a range of non-contact manual or automatic load inspection machines to automate your repetitive, critical-to-quality metrology inspection tasks.

Minimise the time your quality team spend carrying out repetitive off-line CMM inspections with IVS automated metrology inspection. Free your engineers to do what they do best, while our systems take care of the repetitive inspection process.

Device Quality Inspection Machines

Fully automated high-speed vision inspection machines with integrated hopper, bowl feed and dial plate for precision quality control checks and sorting of devices, components and pharmaceutical products, fully validated to GAMP standards.

Ideal for automated quality control inspection and sorting of devices. From surface imperfections, shorts and flashing through to dimensional checks, shape quality and assembly conformance.

Vision Inspection Benches

Manual or auto-load inspection benches for semi-automated or manual and low volume manufacturing lines. Quality control and poka-yoke inspection for medical device products following assembly operations.

Non-contact measurement and inspection machines provide peace of mind for manufacturers by providing accurate scanning, inspection and reporting in one. Reports are generated for individual parts, giving full inspection history and validated results.

Semi-Automatic Inspection Machines

Semi-automatic visual inspection of ampoules, vials, bottles, cartridges and syringes. Automatic handling for visual quality control of pharmaceuticals. Designed to help an inspector with the presentation and pre-rotation of the product to reduce fatigue and allow large batches of products to be presented for inspection. All containers shapes and sizes can run on the machine.

Allows for the simultaneous inspection for many contamination criteria, including: dark contamination, particulate matter, glass defects, particles, fibres – as well as for cometic and container damage such as cracks, inclusions and air bubble. Highest standards in the quality control of pharmaceutical products, for high speed visual inspection.

In-Process Inspection Machines

Achieve precision assembly verification and conformance of your products to specification. Conveyor in-feed vision inspection machines designed for automated quality control following assembly and build operations in medical device manufacture.

IVS inspection machines utilise state-of-the-art machine vision technology to provide mission critical quality checks across the medical device and pharmaceutical manufacturing sector, making precise quality decisions automatically.

Contact Lens Inspection

Quality control for lens manufacturing. Adaptable 100% machine vision inspection systems for complete contact lens quality checks across the entire production floor. IVS provides tools to detect and mitigate unexpected quality shifts.

With adaptable HD cameras to provide inspection for all contact lens material types, IVS vision systems inspect at high precision, reviewing the raw contact lenses for flaws and defects in real time. Our vision systems are very easy to program, are highly accurate, offer easy maintenance and provide peace of mind in final contact lens quality acceptance.

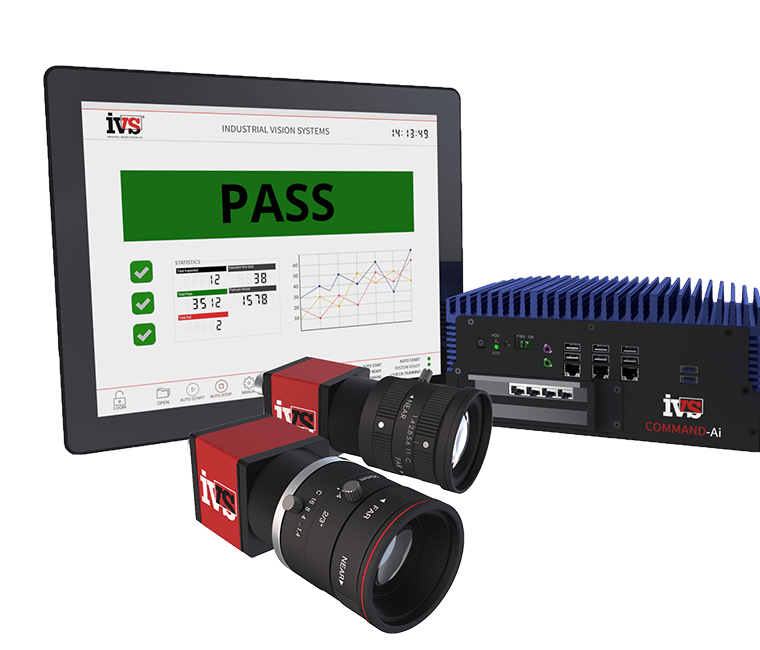

IVS-COMMAND-Ai™ Vision Systems

Deliver immediate improvements to your medical device and pharmaceutical manufacturing process, enabling faster production, without defects and at lower cost.

Easy-to-use vision systems to find and fix manufacturing issues. Save time and money in production. Intercept defects, detect quality shifts and improve production yields, while reducing rework and increasing quality.

Designed for easy validation in medical device and pharmaceutical production lines.

Interested in Medical Device and Pharmaceutical Inspection Solutions?

Get in touch today so we can answer and questions you have regarding our medical device, pharmaceutical and healthcare machine vision systems. See how they can save you money, protect your brand and increase your yield.

Send us a message and we will respond as soon as possible.

Have a Question? Get in touch

World Class Training & Support

IVS is committed to world-class-excellence in product training and support services. Our brand-new state-of-the-art facilities providing classroom and application training.

Delivered by a team of experienced professional technical instructors, our vision system training courses feature a combination of practical workshop exercises and classroom-based learning. Comprehensive training manuals and certification are provided for each delegate. Courses can be tailored to your individual requirements and delivered at your premises on a mutually-agreed date.

Validation Services

FDA and GAMP Validation. 21 CFR Part 11 Compliance. IVS systems and machines are designed according to GAMP & FDA validation, we follow the standard International Society of Pharmaceutical Engineering (ISPE) guidelines. Allow IVS to take care of the validation of the vision project, leaving your engineers to get on with their own busy schedules. By using original IVS validation services, manufacturers can ensure that their vision systems are tested and proven to the highest standard in a timely and cost-effective manner.

Integrated medical device and pharmaceutical inspection systems and machines – designed, built and installed by our expert engineers.

More about medical device and pharmaceutical solutions

Quality Control in Medical Device Manufacturing.

Medical device production includes many aspects of the manufacturing of a medical device, from designing a manufacturing process, to scale-up, to ongoing process improvements. Production can also include the sterilisation and final packaging of a device for shipment.

While speed and cost-savings are vital to successful manufacturing, quality control is of the utmost importance — particularly as medical device market demands shift towards a more value-driven arena. IVS provide the tools for allowing quality to be built in to the process through the use of machine vision processes. Packaging validation, proving to the FDA that a product is sterile when it ships, is the final step, which again is normally checked by an automated vision system.

Many medical device manufacturers excel in the ideas, concepts, and prototyping phases of product development and outsource the production of components or entire devices to medical contract manufacturers. This is true of established original equipment manufacturers (OEMs) as it is for mid-sized medical companies and start-ups. Contract device manufacturers vary in size and expertise, as well — some comprise small, precise operations specializing in particular materials or components, while others are massive cleanroom facilities equipped for large-scale production.

Whatever the size, all companies require validated, reliable machine vision solutions as a corner stone for production. Protecting brand, guaranteeing production efficiency, and delivering 100% quality to the customer and consumers. Trust IVS to help deliver your ideal production process.

What medical device and pharmaceutical products can be inspected with IVS vision systems?

Life-saving devices, quality-of-life devices as well as drug delivery systems are all inspected with IVS machine vision solutions. These include syringes, syringe assembly parts, bodies, needles, stents, implants, surgical tools, orthopaedic joints, contact lenses, test kits, blister packs, pills, wound dressings, medical dressings, health equipment and product packaging. Whether you’re an orthopaedic manufacturer requiring surface and metrology checks, or a sub-contract medical device production company needing packaging label checks, we can provide you with a proven, validated automated inspection solution.