Robot Control

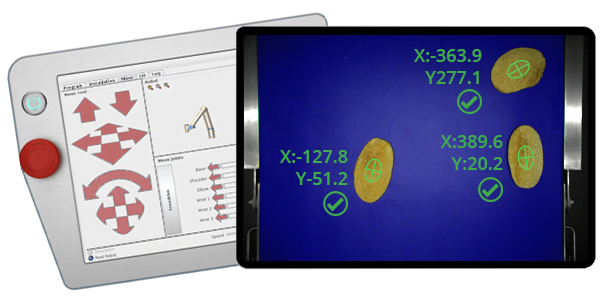

Vision guided robots enable a flexible approach to part handling and product changes, eliminating the need for costly precision fixtures and allowing different parts to be processed without changing tools.

Machine Vision Applications

Robot Control

Robot Control is the ability to accurately determine the position of parts to direct robots, find fiducials, align products and provide positional adjustment feedback using 2D and 3D machine vision. Robots can work alongside humans, optimise processes and carry out time-consuming and intricate tasks.

Vision gives robots “eyes”

Typical Robot Control Vision System Applications

- Location for pick-and-place requirements

- Robot guidance

- Tracking parts on conveyors

- Bin picking

- Automatic palletising and depalletising

- Guidance for collaborative robots

- Guidance for component assembly

- Product and large sub-assembly inspection

- Fully automated inspection tasks

Latest Generation Industrial and Collaborative Robots

Robot Control Vision Systems

Machine vision robot control is utilised to give robots eyes when vision is combined with robotics, robots can track, pick, and place moving or awkwardly situated parts. Robots can also be used to aid the machine vision inspection process, by inspecting hard to view areas of parts or simply removing the need for multiple fixed cameras. Even the most difficult parts can be located using the latest generation of 3D sensors and algorithms, allowing for accurate and dependable bin picking and product placement.

Simple and reliable systems designed by experts

Explore some of the key features and benefits of using an IVS system for robot control

Repeatable and Accurate

Improve your processes by introducing a robot to repeatably pick, place and inspect parts with precision accuracy.

Around The Clock Operation

Industrial robots and cobots can endure 24/7 operation, guaranteeing your processes are performed accurately around the clock.

Fixed Hardware Reduction

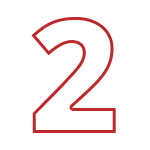

To check different regions of interest, one robot can be equipped with cameras, LED lights, and laser projectors, reducing the need for multiple stationary cameras and lights.

Robot Control Using Machine Vision

Robot Guidance – Vision Guided Robots

IVS has completed projects using collaborative industrial robots such as the Universal Robots UR3, UR5, and UR10, which enable real-time positioning and quality inspection. This latest generation of collaborative robots offer easy programming and are safe to use with operators.

IVS also integrate a range of traditional robots, including ABB, Yaskawa, Kawasaki, Huhtamaki, Staubli, etc. These are typically used in high-speed pick and place applications.

Robot guidance and part navigation can be carried out in 2D, 2.5D and 3D. Robots receive high-precision feedback from IVS robot guiding and alignment systems. Using industry-leading machine vision techniques to detect and align components, patterns, and fiducials fast and precisely, even under harsh conditions.

Vast Application Experience

The Benefits of Machine Vision Robot Control

For quality control checks, IVS can supply highly flexible comprehensive vision inspection cells utilising state-of-the-art robots and machine vision technology.

Using the latest robot technology combined with precision vision sensors, Industrial Vision Systems’ robot inspection cells allow you to automate repetitive and crucial inspection activities. Using the latest collaborative robot systems, the machine can even work alongside an operator.

Robot inspection cells can inspect numerous sides and internals of any product with precision accuracy, high-resolution vision systems enable total coverage even for large and difficult-to-access areas. Different focus depths and fields of vision are possible with liquid lens autofocus technology.

Our robot inspection cells are simple to configure, quick to set up and provide peace of mind for final quality inspection in numerous positions or pick-and-place robot applications.

Belt Picking & Part Removal

The Complete Solution Package

Using 2D or 3D analysis, quickly pick parts from belts, allow handling robots to grab and sort a wide range of objects, including food, packages, and cartons, as well as moulded parts, machined components, and miscellaneous products. Our vision systems provide robots with the information they need to determine quality, such as position, volume, and characteristics. All robots, including ABB, KUKA, Yaskawa, Staubli, Mitsubishi, Fanuc, and UR, are easily integrated. Our contour matching technology makes it simple to find and pick products off conveyors, belts, and lines.

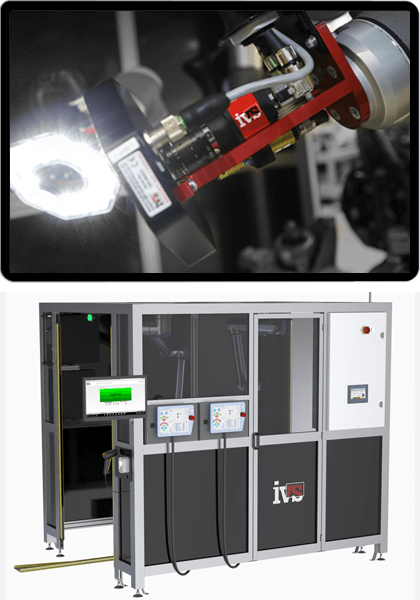

Robot Bin Picking

Pick and Place Any Part

Relieve operators from tedious and time-consuming bin picking, machine loading, stacking, kitting and assembly tasks. These tasks are all possible with integrated robot vision solutions. Automate any task with 3D vision picking, which can handle random objects from bins and stillages while automating robot movement, avoiding collisions, and picking the most complex components.

We integrate the entire system to reduce risk, and our engineers have vast experience with automated 3D bin picking and loading. We use our cutting-edge 3D bin picking solutions to control recognition, gripping, and robot motion to automate the unloading of bins reliably and efficiently.

More about IVS machine vision robot control solutions

The employment of industrial robots has risen considerably in recent years. Co-bots have also grown in popularity as a result of the demand for a versatile robot that can work alongside people. Industrial robots have become a cornerstone in the modern production line, thanks to the demand for ever more flexible production control and the emergence of flexible manufacturing.

Because robots can switch between product ranges and component kinds, they require “eyes” to observe and discern between product types in real-time. In addition, there is a push to expand the use of automation and reduce the usage of manual labour in manufacturing. Robots can take over some of the more repetitive manufacturing and assembly duties, but as speeds and complexity rise, a robot’s capacity to comprehend a complex scene becomes increasingly difficult.

IVS has a track record of successfully integrating vision systems with some of the world’s leading robot manufacturers. We provide complete solutions that include the hardware, software, programming and testing required to complete and simplify your production task. We also carry out in-depth planning to ensure our systems meet your requirements.

What is a collaborative robot?

Robots designed for direct contact with humans in a shared area are called collaborative robots, or cobots. These differ from traditional robots, where they would need to be enclosed with a safety enclosure. Cobots work side by side with humans, perform a variety of tasks and offer a safe working environment. Safety is our priority, therefore we provide a comprehensive risk assessment with every robot system.

How do you control and link vision systems to a robot?

We can use a PLC to control robots or provide robot waypoint data directly from our vision software, providing us with a lot of flexibility in terms of the solutions we can supply. Within the robot’s software package, positions and paths may be created. Furthermore, each position can be designated a specific safety position to ensure that the system operates safely even in exceptional circumstances. Communication with robots is made as simple as possible, all of our software is intuitive and simple to learn. All of this can all be set up by our in-house experts and training can be provided if required.

Why add industrial vision onto a robot?

You can give a robot “eyes” by adding vision devices to it. This in turn avoids the need for expensive and complex fixtures and nests by defining a specific location for the robot to look for objects. Vision devices can also be fitted to conveyor belt gantries to pre-scan the scene before the robot picks a product, ensuring a precise pick every time.

Robotic automation’s adaptability allows the robot to adapt to wider variations in part type, shape, size, and placement, lowering the manufacturing cell’s complexity. As a result, integrating a vision system expands the range of applications, such as robot palletising and de-palletising.

What hardware can be integrated with a robot control vision system?

The following equipment can be integrated directly onto the robot head:

- Custom grippers, vacuum pads, or even needle grippers for even the most difficult pick and place applications

- LED illuminators

- Laser projectors

- Standard or variable focal length lenses: Our robotic inspection systems can employ standard or variable focal lenses. Variable focal lenses allow for rapid focal length changes, again minimising the need for multiple fixed-position cameras

- Screwdriving systems

- Applicator heads for glue, sealants etc

What robots are compatible with vision systems?

All of the main robot manufacturers, including ABB, Kuka, Kawasaki, Yaskawa, Fanuc, Omron, Franke Emika, Hanwha, Universal Robots, Doosan Robotics, Staubli, Nachi, Aubo, Neuromeka, Fanuc, and Hyundai are compatible for use with IVS robot vision systems.