Case Studies

High performance machine vision inspects automotive connectors for bent pins

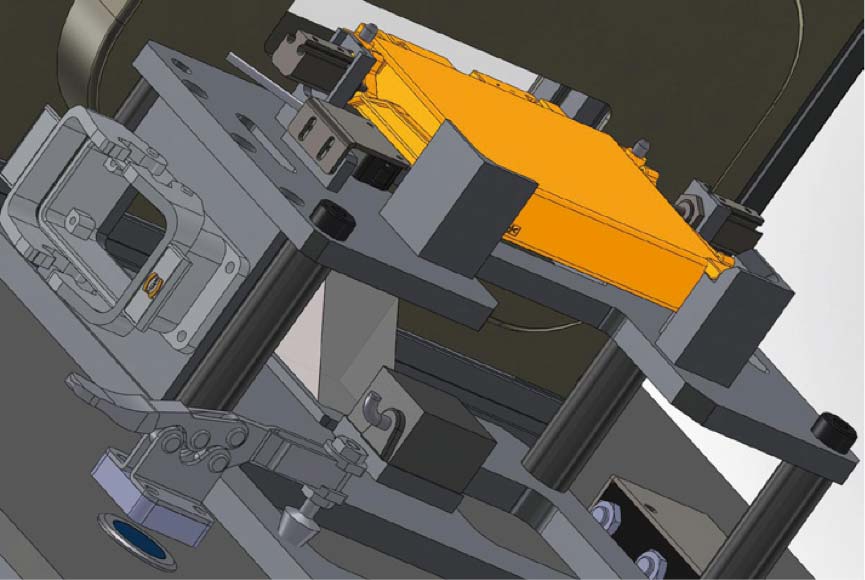

In this system Industrial Vision Systems Ltd have integrated multiple high resolution digital cameras, combined with 4 LED line lights to provide inspection of the end face of electrical modules for bent pins. This system is a final inspection cell for an automotive electronics supplier to confirm that no pins have been bent during the production process. By utilising a vision system, rather than a mechanical method, it means that no material comes into contact with the pins – as there is always a danger with a mechanical method of the inspection process itself causing the pins to bend.

The digital cameras utilise telecentric lenses over a small field of view giving micron level detection of movement of the interface pins in the module. The various angled lights give the ability to process images of the pins in different lighting conditions as well as providing a view of the connector’s datum to measure from.

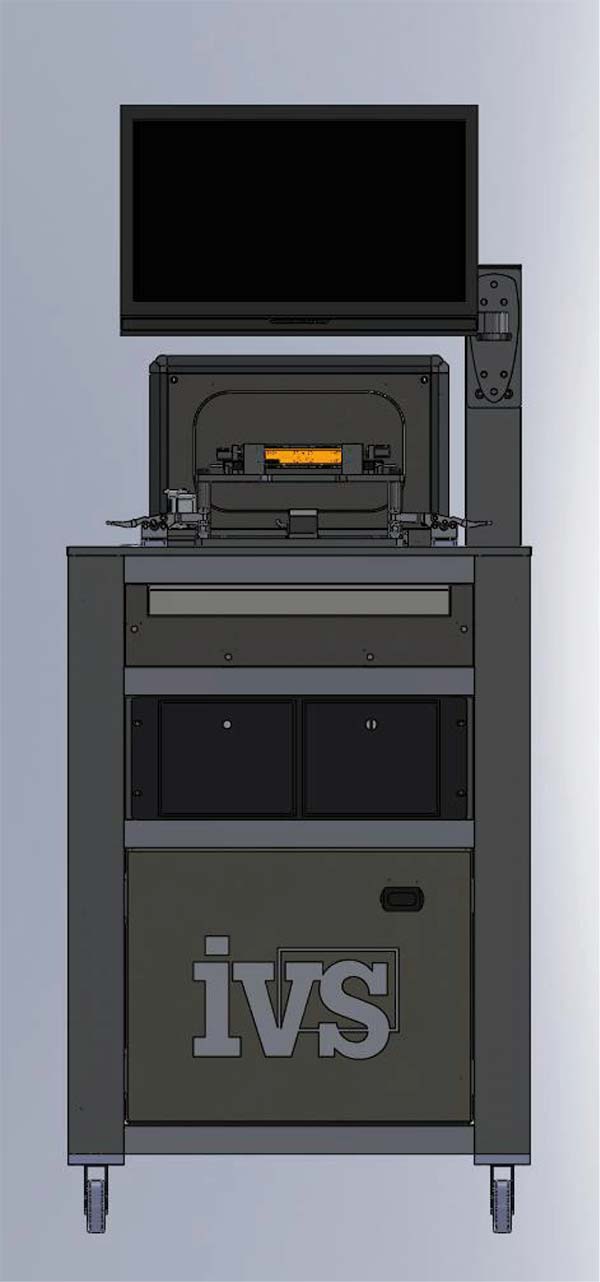

The system is integrated into a standalone machine, with removable tooling to allow different product types to be inspected. The complete vision system is shrouded, with only a “letter box” viewing window, to stop ambient lighting conditions affecting the vision system result.

The machine vision software interface designed by Industrial Vision Systems completes the complex gauging measurement across the pins and a custom designed front end screen is displayed for simplicity for the operator. The system is connected to the factory information system via Ethernet for statistical data upload.