Food & Beverage

Increasing quality and protecting brand reputation in the food and beverage industry through automated visual inspection.

Food and Beverage Industry Solutions

Automated Visual Inspection for the Food & Beverage Industry

Protect your reputation, increase quality and stop costly product recalls with 100% automated vision inspection of every product. State-of-the-art AI-enabled vision technology safeguards your factory output, providing you with eyes on production, at all times. Bad product can adversely affect how customers and consumers perceive food and beverage quality, safety, and value – and can result in costly product recalls for the manufacturer. Protect your production now, with our automated vision inspection systems, running 24/7 – and they don’t get tired!

Automated Vision Inspection Made Easy

Typical Food & Beverage Vision Applications

- Portion control inspection

- Chewing gum checking

- Branding and livery checks

- Food mix-up controls

- Date, lot and part number verification

- Pizza topping verification

- Content checking

- Bottle fill level inspection

- Damaged carton inspection

- Foreign object detection

- Packaging measurements and verification

- Tray and insert checks

- Seal inspection

- Validating fruit tub filling

- Detecting broken products

- Meat and poultry inspection

- Food contamination checks

- Empty can verification prior to fill

- Glass bottle checks

- Keg leakage inspection

- Chocolate box verification

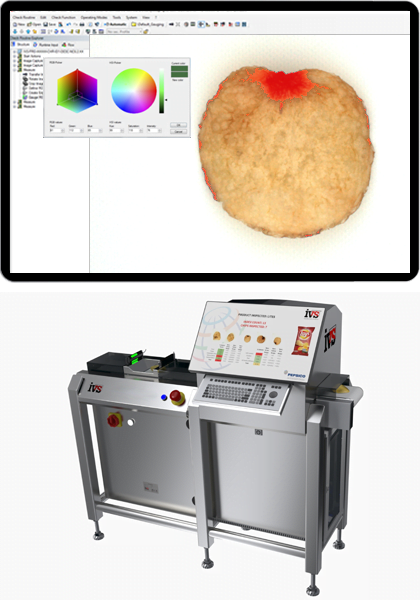

- Chip and Crisp visual defect checks

- Label mix-ups verification

- Can inspection

- Dimensional checks of glass bottles

- Cap and label tilting detection

- Dairy bottle checks

- Colour analysis of food contamination

- Positioning of food in packaging checks

- Verifying cover films

Simple and reliable systems designed by experts

Explore some of the key features and benefits of using an IVS system for your food and beverage production process

- Prevent Costly Recalls

Stop customer recalls and sleep easy at night knowing every part of your production is 100% checked automatically, before it leaves your premises.

- Visualise Data

Find and detect issues at source. Backed with end-to-end failure analysis tools, management statistics and remote real-time build monitoring, all in a single simple platform.

- Protect Your Brand

Your consumer reputation is everything. Protect your brand and stop bad products exiting your factory. Increase efficiency and reduce reliance on operators in production.

Right First Time

Stop product recalls and increase quality

We provide quality control vision systems into many diverse food industries, ranging from snacks and dry food to fresh and frozen food applications. With increased pressure from consumers, supermarkets and government for manufacturers to deliver a “right first time” product IVS can provide the 100% inspection for your production process.

IVS design, manufacture and install a wide range of vision inspection solutions as well as the full control to allow our systems to integrate directly with your other machinery and production processes. Our vision systems are capable of exceptional speeds while maintaining high accuracy and can switch automatically between different products and processes, allowing food manufacturers to handle many products on a single line.

Our class-leading quality control vision systems provide peace of mind in providing end-of-line quality control to finite detail. We save our clients’ money by installing a vision system which is robust and reliable, and we save them a lot of time allowing immediate payback on quality and yield.

Meet Food Standards

Trusted technologies to automate quality better

Meet your food standards requirements providing inspection in a transparent and objective manner, validated to the correct level. Many food and beverage businesses face challenges at the field level with enforcement agencies and therefore there is a need to adopt transparent automated inspection solutions which not only provide the business with 100% inspection, but provides reliable and traceable data relating to rejects, production statistics and error reporting. Allowing the food manufacturing to drill down on the specific aspects for closed loop process control.

To minimise downtime and produce consistently high-quality, safe goods with fewer defects and waste, successful food and beverage operations embrace advancements in product quality inspection, packaging inspection, assembly verification, allergy management, traceability, and food safety. IVS® machine vision systems provide effective solutions for ensuring product quality and safety, maintaining package integrity, managing allergies, and maintaining traceability.

Lifecycle Inspection Solutions

Total traceability from farm to shelf

In the food industry, total traceability is required from farm to shelf. Identifying quality factors is frequently an inaccurate, uneven, and slow process for humans. Machine vision systems don’t just scan the food; they also verify that the items match the stringent criteria set by food organisations by continuously monitoring them. Our solutions are used through the entire manufacturing cycle, from checking the incoming raw goods for contamination, through to portion control, packaging and date code verification.

Our vision inspection systems have been specifically designed to ensure that your merchants and customers can trust the quality of your products. For packed products, ensuring product integrity is essential. Product failure initiates a chain reaction when your failed merchandise is sent out the door. Customers complain, things are returned at a high expense, and entire batches of products are thrown away as a result of this. Vision inspection stops failures and allows you to sleep at night!

Interested in Food & Beverage Inspection Solutions?

Get in touch today so we can answer any questions you have regarding our food and beverage vision solutions and how they can save you money, protect your brand and increase your yield.

Send us a message and we will respond as soon as possible.

Have a Question? Get in touch

More about IVS inspection for the food beverage industry

Product inspection and inline quality assurance

In food and beverage manufacturing processes the production process is all about speed, therefore inline product inspection is the only choice for your quality assurance. Properly integrated into the process, our product inspection systems enable you to achieve the highest speeds and the best quality – on a continuous basis. You know that, for the individual inspection of your products, you have only seconds for precise transport, positioning and inspection.

With our automated vision inspection, you are therefore well positioned in terms of quality assurance and performance for 100% inspection. In fact, our solutions become your eyes – keep an eye on all legal regulations – assuring you pass every check with flying colours at speed. As a food producer, your priority is food safety, so our priority is automated food inspection in your production process.

Regulation (EC) No 852/2004 requires you, as a food producer, to determine critical control points in your production process- i.e. to have “the measures and conditions necessary to control hazards and to ensure fitness for human consumption of a foodstuff taking into account its intended use’. Possible controls include the detection of foreign bodies (e.g. ferrous, non-ferrous metals, stainless steel, glass, ceramics, stones) and inspection of the packaging. To ensure that only first-class products leave your company, we have developed high-speed automated inspection vision systems that detect all aspects of food and packaging quality.