Automated Vision Inspection Benches IVS-MALi-A

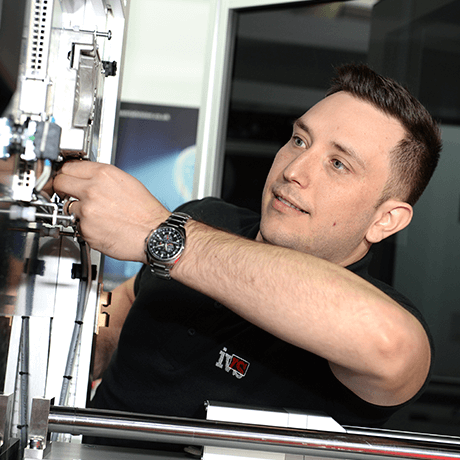

Manual or auto load inspection benches with integrated fixtures and vision system cameras for fully automated quality control and poka-yoke inspection following assembly operations.

Our fully integrated inspection benches utilise state-of-the-art machine vision technology for critical quality checks – MALi – from Industrial Vision Systems lets you automate repetitive and critical inspection tasks following a manual process or assembly. The system can be set-up as a stand-alone bench for manual loading or a fully enclosed machine dependent on the application requirements. The height of the unit can be adjusted for operators to sit or stand for the loading and unloading process.

MALi uses artificial intelligence to provide critical quality decisions automatically. With adaptable vision sensors to provide inspection from any angle, MALi inspects even the most mundane tasks, freeing up your operators and technicians time to add value to other stages of automotive manufacturing.

Our vision inspection benches are very easy to program, offer fast set up and provide peace of mind for in-process assembly inspection operations.

Ideal for automated quality control checking

Inspection of Engine management modules

Low batch run automotive assembly checks

Plastic assembly quality control

Dimensional gauging on bearings

Airbag and associated part quality checks

Small automotive component inspection

Sub-assembly build quality

Automotive electronic module checks

Clips, bushes, caps, nuts, fasteners presence

Character recognition and label checks on smaller parts

Springs, coils and insert inspection

Connectors and pin checks

Automotive console parts

Injection moulded shorts and flash

Simple solder and PCB checks

Full assembly conformance

Off-line batch checks

Features and benefits of automated vision inspection machines

Frees up mundane inspection tasks

Store and review HD quality images of every product manufactured

Operators can manually load or auto load

Guarantees quality leaving the factory

Need expert help & advice?

We offer engineering advice and support for all machine vision applications. Call us on +44 (0) 1865 823322 or enquire below

About IVS

Founded in 2000, IVS is now one of Europe’s leading specialists in inspection machines and artificial intelligence vision products – supplying customers all around the world and building an unrivalled reputation for innovation, quality and precision in machine vision systems for inspection, guidance and identification.