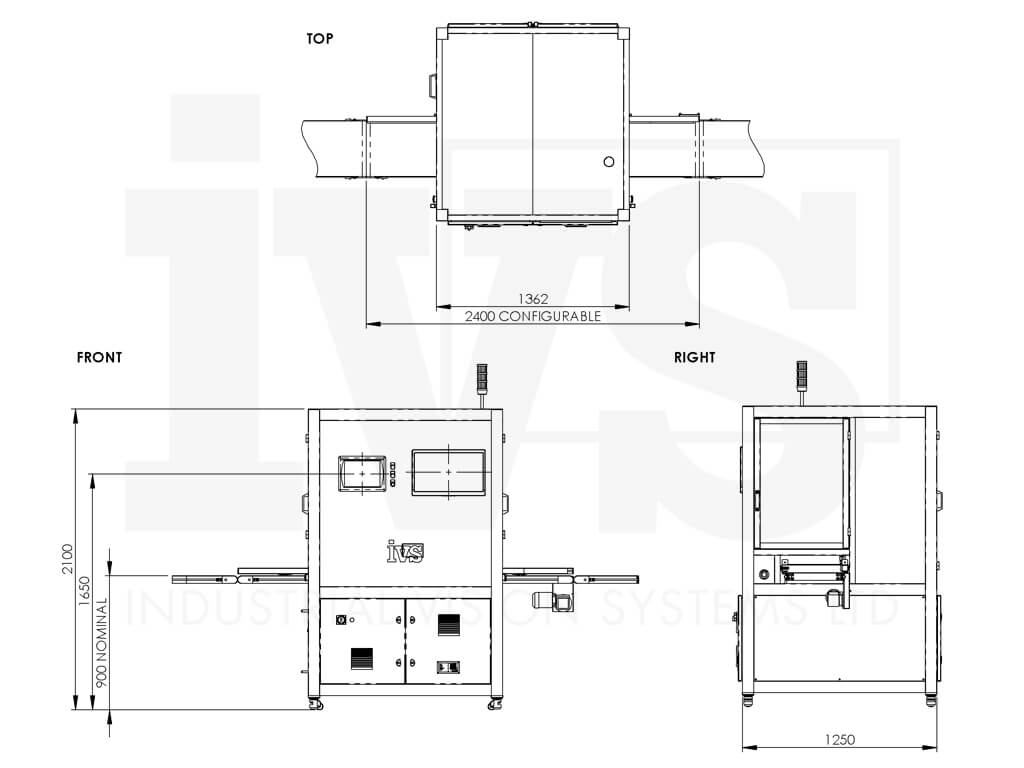

In-Process Vision Inspection Machine IVS-INPi-A

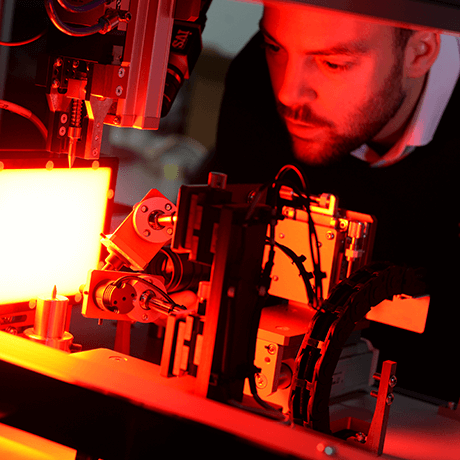

A fully automated vision inspection machine with conveyor in-feed, multiple axis and integrated reject for automated quality control checks following assembly and build operations. Designed to be used in-line as part of the production process or as a stand alone autonomous inspection solution. Can also be used with products which are tray/pallet mounted.

INPi-A uses artificial intelligence to provide mission critical quality checks across the automotive manufacturing sector, making precision quality decisions automatically.

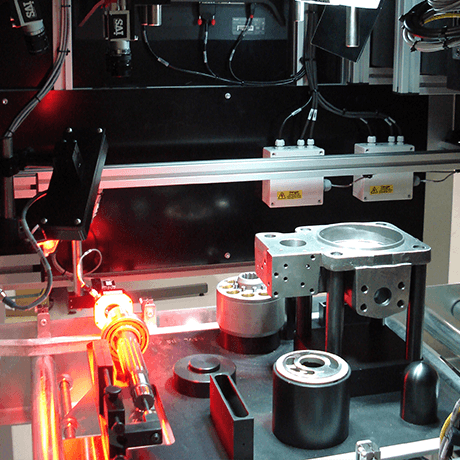

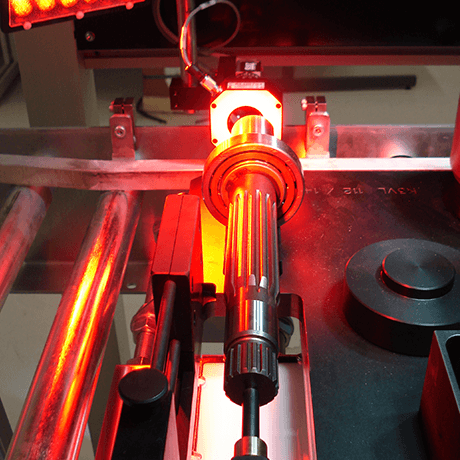

INPi-A inspects at high speeds with precision detail allowing full automatic quality control as part of the in-line build process of automotive manufacturing.

Ideal for automated in-process quality control inspection

Automotive component build quality checks

Surface inspection checks

Dimensional measuring of components

Shorts and flash inspection checks

Label and markings quality inspection

Bead checks on parts

Presence verification of key parts

Assembly conformance

Insert inspection checks

Debris quality inspection

Character recognition, verification and label checks

Presence conformance

Rogue part detection

Colour and paint quality checks

Scratch and inclusion inspection

Features / Benefits

100% automated inspection

Guarantees final quality leaving the factory

Checks full build quality in-process without operator intervention

Amazingly sharp HD image quality

Need expert help & advice?

We offer engineering advice and support for all machine vision applications. Call us on +44 (0) 1865 823322 or enquire below

About IVS

Founded in 2000, IVS is now one of Europe’s leading specialists in inspection machines and artificial intelligence vision products – supplying customers all around the world and building an unrivalled reputation for innovation, quality and precision in machine vision systems for inspection, guidance and identification.