Our Products

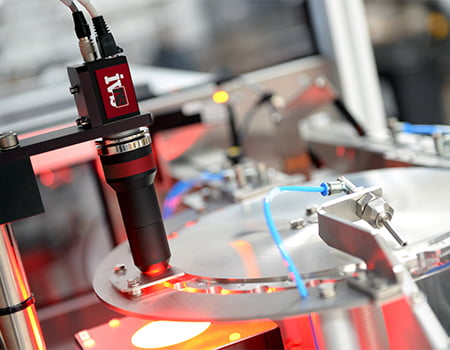

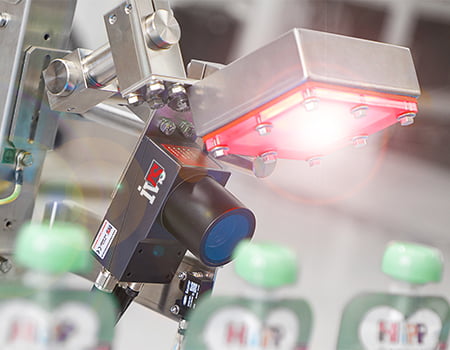

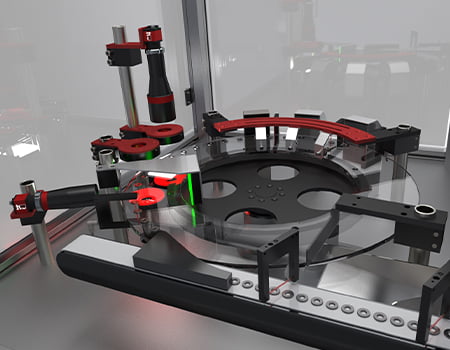

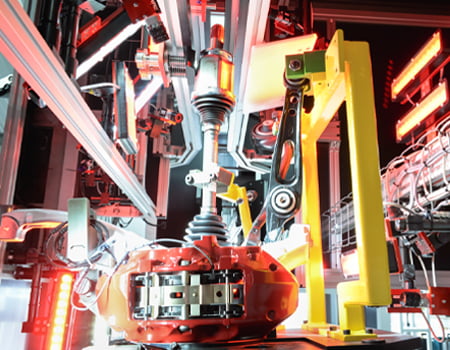

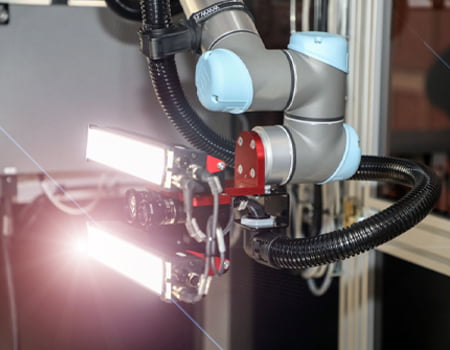

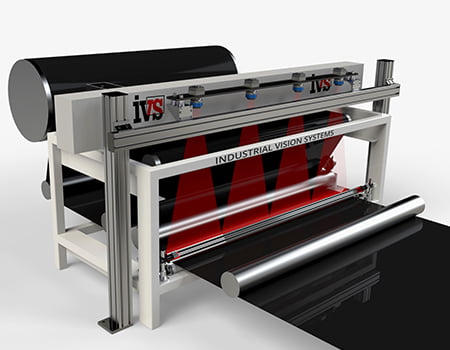

Immensely powerful, state-of-the-art automated quality control machine vision inspection systems and machines.

Our family of solutions covers everything from vision system component supply up to fully customised systems designed, built and installed by our expert engineers. Protect your brand, increase quality and lower costs.

Whichever way you look at it, we’ve got you covered.

Talk to a machine vision expert today

Our experts have deployed solutions in all industries across the world. Find out how we can help you with your vision inspection needs.