Sub-Assembly Vision Inspection IVS-ASAi

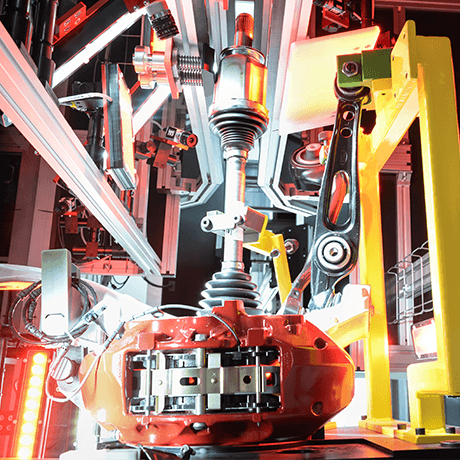

A fully automated complete sub-assembly inspection and conformance inspection cell, providing 100% quality control checks using machine vision.

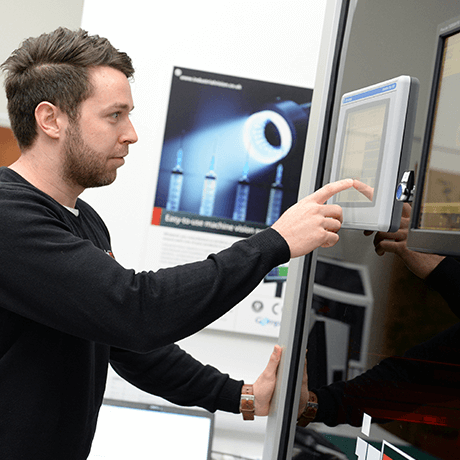

The quick to install and flexible machine vision solution from Industrial Vision Systems lets you automate repetitive and critical inspection tasks covering complete sub-assemblies to check conformance to manufacturing standards. Our machine uses latest generation artificial intelligence vision systems and sensors to provide mission critical quality inspection criteria across the entire automotive sub-assembly build cycle.

With adaptable cameras and vision sensors to provide complete coverage of even the largest parts, our sub-assembly vision machines inspect from complex to the most mundane tasks, freeing up your employees’ time to add value to other stages of automotive production.

Our sub-assembly inspection vision systems are very easy to program, offer fast set up, are highly accurate and provide peace of mind in final quality acceptance in automotive manufacturing.

Ideal for automated quality control checking of sub-assemblies

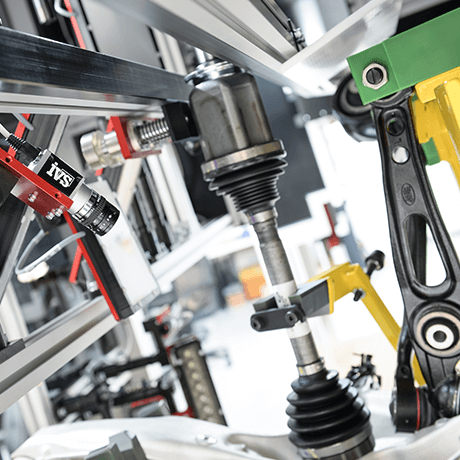

Automotive sub-assemblies

Complete engine inspection

Front axle corner assemblies

Gearbox units

Front fascia and console components

Drivetrain assembly parts

Body in white parts

Alternator assemblies and parts

Automotive electronic assemblies

Complete sub-assembly conformance to manifest

Caps, inserts, screws, washers and nuts

Automotive radiator parts and assemblies

Measurement of critical dimensions

Color matching of components

Headliner and plastic part checks

Code and ID Conformance

Type verification

Features / Benefits

100% inspection of every assembly manufactured

Save key statistical data and information

Guarantees quality leaving the factory

Utilises state-of-the-art artificial intelligence vision sensors

Need expert help & advice?

We offer engineering advice and support for all machine vision applications. Call us on +44 (0) 1865 823322 or enquire below

About IVS

Founded in 2000, IVS is now one of Europe’s leading specialists in inspection machines and artificial intelligence vision products – supplying customers all around the world and building an unrivalled reputation for innovation, quality and precision in machine vision systems for inspection, guidance and identification.