When you pick up a pill or tablet, it may appear small and modest, but have you ever realised how much precision goes into making it perfect? In the pharmaceutical industry, the quality of pills and tablets is determined by more than just their chemical content. These tiny goods must also meet demanding size, shape, weight, and appearance requirements. A single flaw or defect can jeopardise not just the product’s integrity but also consumer trust, hence quality control is a major responsibility.

Automated vision technology is critical in pharmaceutical manufacturing because it ensures precision and compliance throughout the entire process. These systems are critical in modern manufacturing, delivering innovative solutions that ensure each pill fulfils stringent industry standards and regulatory criteria. From detecting cosmetic faults to following tight MHRA, FDA, and GxP criteria, these advanced vision systems add precision, speed, and dependability to an otherwise daunting process.

Why Does Perfection Matter in Pharmaceutical Manufacturing?

In the pharmaceutical sector, flaws are more than just an aesthetic issue. A tablet with obvious flaws, such as black spots, cracks, or discolouration, may raise concerns about its quality and safety. Furthermore, any change from the specified dimensions, weight, or appearance may have an impact on the medication’s efficacy or raise regulatory concerns.

Pharmaceutical firms are expected to follow strict rules such as MHRA, GAMP, and GxP laws. Automated vision systems meet these standards by performing speedy and comprehensive inspections, decreasing human error, and ensuring quality control consistency. Manual inspection is just not possible for production lines that run at high speeds, hence automation is an integral aspect of the process.

Tablet and Pill Inspection: A Complicated Process

Pills, pills, and capsules come in all shapes and sizes. Tablets typically measure 5-12mm in diameter and 2-8mm thick, with curved tablets reaching lengths of up to 21mm. Capsules, on the other hand, are classified according to their size, which typically ranges from size 0 (biggest) to size 5. Regardless of these variances, producers must detect cosmetic flaws down to the nano level—a feat well beyond the human eye’s capabilities.

Some frequent defect categories that vision systems must recognise are:

- Surface problems include dirt, foreign particles, scratches, cracks (lengthwise and diagonal), splits, and holes.

- Anomalies in shape include dents, bends, double capping, and collapsed tablets.

- Color discrepancies, including discolouration and uneven finishes.

How Does Automated Vision Technology Work?

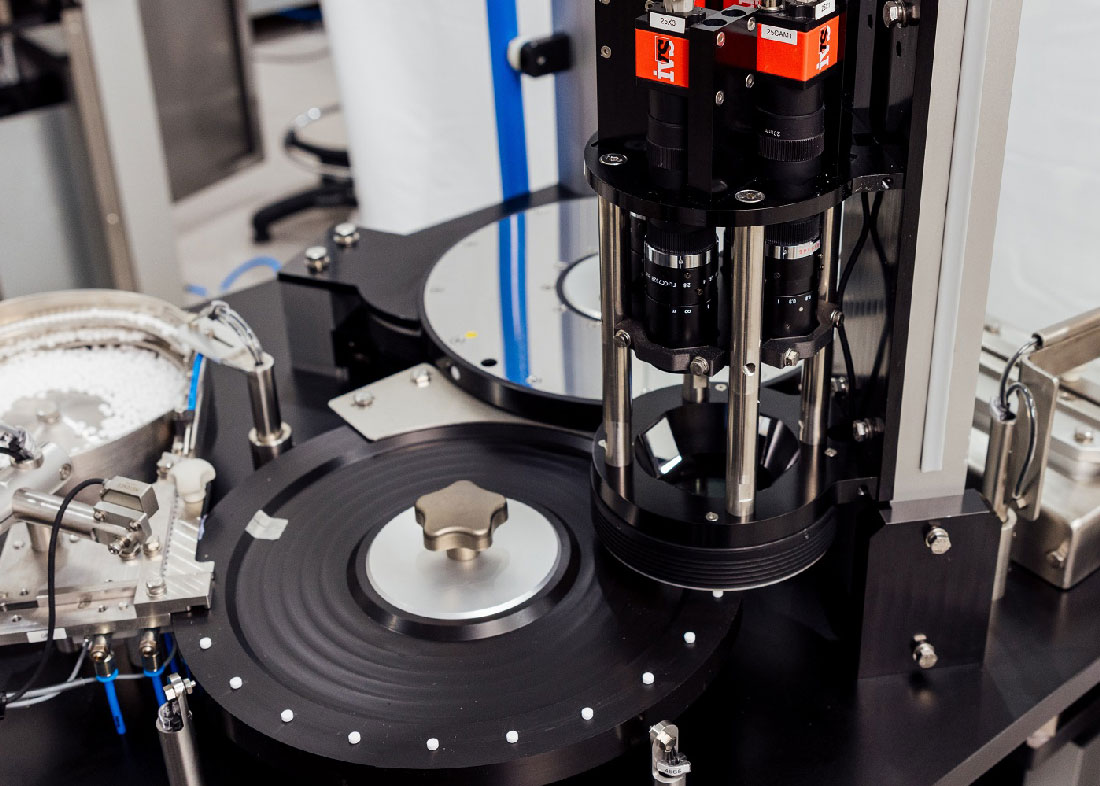

The inspection procedure starts with a high-speed feeding mechanism. Pills are carefully transferred from hoppers or bowls into the inspection channel and positioned for best viewing by the vision system. To guarantee both sides of the pill are inspected, modern systems frequently use a two-step process:

-First Side Inspection: A vacuum dial plate holds the pill in place while cameras take photos of the top surface.

-Second Side Inspection: The pill is moved to another plate and hung securely through a vacuum while cameras analyse the bottom.

This system ensures that each tablet is properly scrutinised with no blind spots.

The Magic of Multi-Camera Vision Systems.

The true value of automated vision technology comes from its capacity to deliver a 360-degree image of each tablet or pill. Multi-camera modules, which are frequently coupled with custom optics and mirrors, enable for thorough inspection. Manufacturers may take images of all sides and angles of the pill by strategically positioning cameras and mirrors, resulting in eight distinct perspectives of a single product.

These photos are evaluated by advanced algorithms that detect even the smallest imperfections, guaranteeing that only faultless products make it into packaging. The system’s capacity to eliminate blind spots is vital for performing the high-speed, high-accuracy inspections demanded by current pharmaceutical manufacturing.

Beyond Detection: The advantages of vision systems

Automated vision systems offer distinct benefits that correspond to the pharmaceutical industry’s rigorous requirements:

- Vision systems can inspect hundreds of pills per minute without sacrificing accuracy, resulting in optimal manufacturing line efficiency.

- Advanced imaging can detect faults as small as a few microns, invisible to the human sight.

- Real-time data analytics in vision systems help manufacturers spot trends, foresee concerns, and take preventive action to preserve product quality.

- Effective Compliance: Built-in checks linked with FDA, GAMP, MHRA and GxP standards ease regulatory conformity, decreasing the risk of infractions and assuring consistent product quality.

- Vision systems reduce waste by recognising damaged pills early in the production process, saving money and resources.

These specific qualities make automated vision systems indispensable in modern pharmaceutical manufacturing, where precision and compliance are critical.

Innovation on the Horizon

As technology advances, so does the possibility for automated vision systems. Emerging technologies such as artificial intelligence (AI) and machine learning are improving defect detection capabilities by allowing systems to learn from prior inspections and improve with time. Additionally, integration with Internet of Things (IoT) devices enables real-time monitoring and data analysis, giving businesses with actionable insights to further improve manufacturing operations.

Final Thoughts

Automated vision technology is transforming the pharmaceutical industry by assuring that every pill and tablet meets the highest levels of quality and safety. These technologies improve manufacturing efficiency while maintaining consumer trust by combining speed, precision, and innovation.

The next time you take a pill, remember the sophisticated processes and cutting-edge technology that secured its perfection. Automated vision inspection enables manufacturers to confidently provide clean, high-quality products, one pill at a time.