Introduction

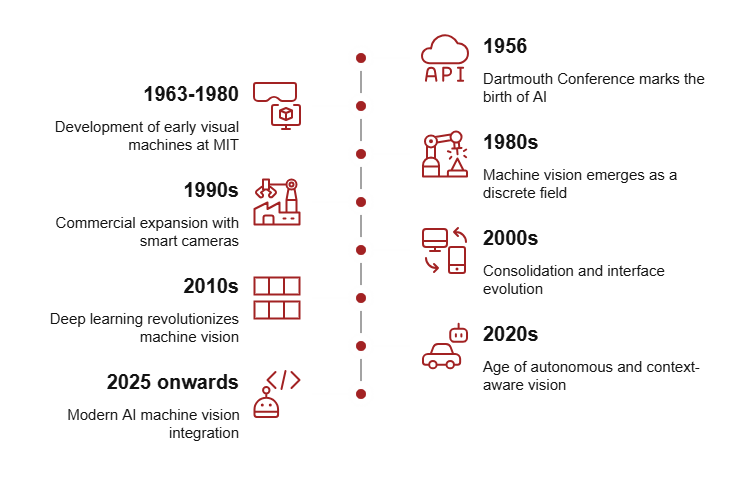

This month, we’re digging into how it all began. The current era of “Smart Manufacturing”, encompassing machine vision and vision systems as a technology, can be traced back to just after the Second World War. In this article, we’re going to see how the field has developed over the last 80 years, ultimately leading to the current trend of “real” AI machine vision.

Machine vision is a crucial subset of computer vision, primarily applied within industrial and manufacturing environments. It enables machines to visually inspect, analyse, and make decisions based on digital images—automating what once required human eyesight and judgement. As computing capabilities and imaging technologies have evolved, so has machine vision, transitioning from a research curiosity to a critical pillar of modern automation. We’ll explore the evolution of machine vision from its conceptual birth in the mid-20th century to its rapid advancements up to the present day in 2025.

Origins: Post-War Foundations (1945–1956)

The genesis of machine vision can be traced back to the broader development of artificial intelligence (AI) in the post-World War II era. The early foundations were laid not with industrial inspection in mind, but rather as part of philosophical and military inquiries into replicating human cognition and intelligence using emerging computer technologies.

Researchers began to depart from biological models like artificial neurons, instead focusing on how human thought could be more effectively emulated using modern digital computers (modern for the time!). During this phase, the concept of a machine “seeing” was not yet considered. The vision element would only emerge as AI matured.

Early AI and the Seeds of Vision (1956–1963)

A pivotal moment occurred in 1956 at the Dartmouth Conference, widely considered the birth of AI as a field. This event attracted pioneers from Carnegie Mellon, MIT, Stanford, and IBM, sparking an explosion of research.

Two major branches emerged—logical reasoning and pattern recognition. The latter would eventually evolve into machine vision. LISP, a programming language developed at MIT for AI applications, became instrumental in early image-based reasoning experiments, laying the groundwork for future vision systems.

The 1960s–1970s: First Visual Machines

Between 1963 and 1980, computer vision began taking form. At MIT, the “Blocks World” experiment marked one of the first serious efforts to enable computers to interpret real-world scenes. Cameras were used to detect blocks, and the system relayed information to a robotic arm—establishing an early link between image analysis and physical action.

David Marr, a British cognitive scientist working at MIT, became a central figure in vision theory during this era. His models of visual perception—emphasising how visual systems interpret depth, shape, and motion—remain foundational in vision science today.

The 1980s: The Birth of Machine Vision as an Industry

By the 1980s, machine vision emerged as a discrete field. The development of image processing technologies and deployment of real systems began to occur in industrial contexts.

The XCON system, developed at Carnegie Mellon for Digital Equipment Corporation, automated configuration tasks and saved the company tens of millions. Meanwhile, MIT spun out “Cognitive Experts” in 1981—one of the first commercial machine vision firms.

Key technological milestones included:

– Transition from LISP to C-based processing on standard microcomputers.

– Emergence of 8-bit greyscale image processing.

– First industrial cameras and plug-in image processing boards.

– The Windows OS revolution, starting with Windows 1.0 in 1985.

However, the industry suffered setbacks—such as the 1988 collapse of Machine Vision International—highlighting the volatility of early adoption.

The 1990s: Commercial Expansion

With the release of Windows 95 and widespread adoption of 32-bit operating systems, the 1990s saw explosive growth in machine vision.

Key trends:

– Broader adoption across electronics and semiconductor industries.

– Sharp decline in hardware costs, making machine vision accessible to smaller firms.

– Emergence of standalone “smart cameras” with onboard processing power.

– Expanding market with integration into quality control and robotics.

These advances allowed machine vision to leave the labs and integrate seamlessly into automated production lines, significantly boosting efficiency and quality assurance.

The Early 2000s: Consolidation and Interface Evolution

By the early 2000s, machine vision entered a phase of consolidation. Key developments included:

– Faster PC hardware and more user-friendly Windows interfaces.

– Migration from code-based libraries to graphical user interfaces (GUIs).

– Ergonomic designs for easy factory-floor integration.

– New digital interfaces like FireWire (IEEE 1394), allowing high-speed image transfer without frame grabbers.

The market grew steadily, supported by increasing demand for consistent quality and traceability across manufacturing sectors.

By 2004, the global machine vision market was valued at approximately $500 million, with projections of near-billion-pound potential by the following decade. However, proprietary systems, capital cost, and the need for highly skilled developers were noted as barriers to broader adoption.

The 2000s–2010s: Smart Systems and AI Re-emerge

From 2004 onward, the machine vision landscape evolved significantly with the reintroduction of AI—this time powered by vast computational advances, cheaper sensors, and big data.

Key milestones:

– Smart cameras became ubiquitous, offering embedded computing and high-resolution imaging in compact formats.

– Machine learning began to enhance image classification, particularly in pattern recognition tasks such as defect detection or surface inspection.

– The rise of GigE Vision, USB 3.0, and CoaXPress allowed faster, longer-distance data transmission between cameras and computers.

– Adoption across non-industrial sectors: medical imaging, agriculture (crop inspection), pharmaceuticals, and automotive (driver assistance systems).

– Growth of 3D vision systems and multi-camera stereo setups for robotics and logistics.

2010s–2020s: Deep Learning and Edge Computing

The last decade brought a seismic shift: deep learning revolutionised machine vision capabilities.

Highlights:

– Convolutional Neural Networks (CNNs) proved highly effective at visual classification tasks, outperforming traditional rule-based algorithms.

– Vision systems began to learn from data rather than being explicitly programmed.

– Open-source frameworks like TensorFlow and PyTorch made it easier to train and deploy custom models.

– Edge computing allowed real-time vision processing on-device, reducing latency and eliminating the need for centralised servers.

– Vision systems became integral to Industry 4.0 (and then Industry 5.0), enabling closed-loop quality control, predictive maintenance, and real-time decision-making.

2020s to 2025: The Age of Autonomous and Context-Aware Vision

In the 2020’s, machine vision is no longer just a tool—it is a strategic enabler for autonomous systems and context-aware intelligence.

Trends defining this era:

– AI-on-the-edge vision systems handle complex decision-making in real-time.

– Integration with robotic arms, drones, and AMRs (Autonomous Mobile Robots) in warehouses and factories.

– Adoption of hyperspectral and thermal imaging in areas such as agriculture, recycling, and security.

– Synthetic data and simulation environments like NVIDIA Omniverse train models without real-world images, solving the data scarcity issue.

– Continued miniaturisation and energy-efficiency improvements make machine vision viable in wearable devices and IoT sensors.

– 5G and cloud-native architectures enable distributed vision networks—real-time data sharing between cameras and AI across facilities.

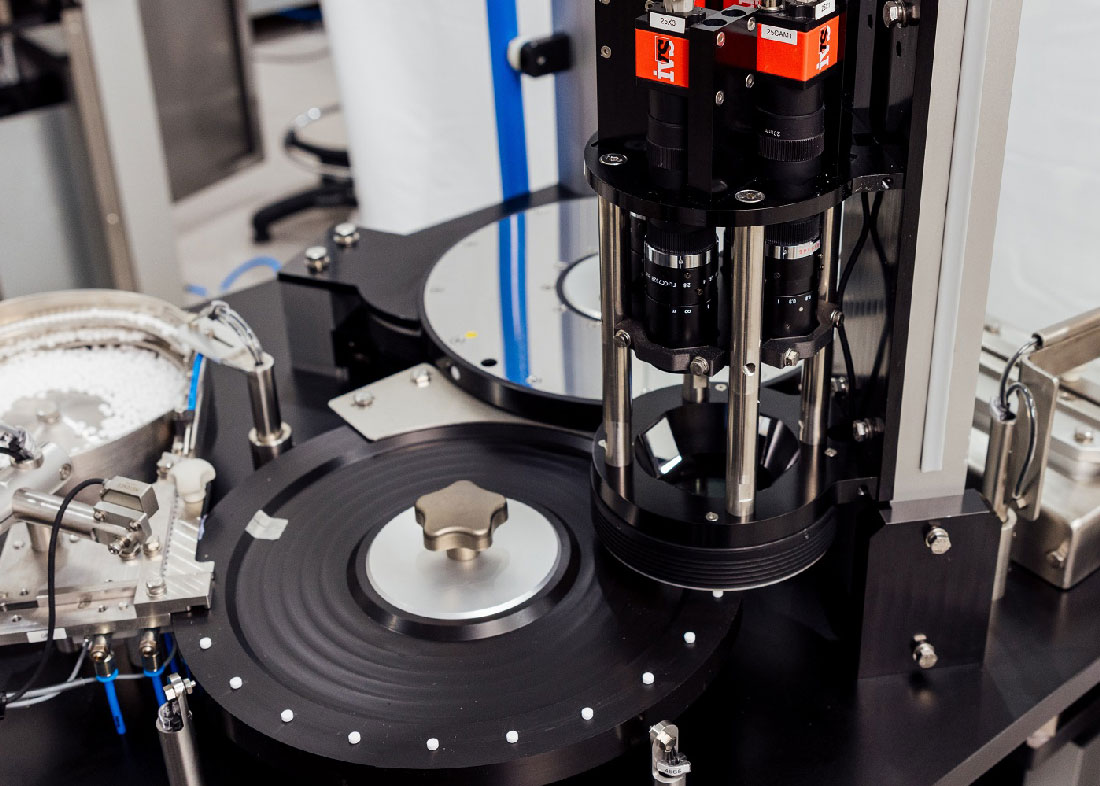

Today, machine vision is embedded in almost every smart manufacturing production line, from inspecting microelectronics to identifying anomalies in real-time during automotive manufacturing. It plays a vital role in ESG compliance (e.g., reducing waste), safety (e.g., human-machine interaction monitoring), and even creative applications like art restoration and retail analytics.

2025 onwards: Modern AI machine vision

Modern machine vision AI systems can be integrated across a wide range of industrial technologies. They offer seamless compatibility with industrial cameras (both 2D and 3D), programmable logic controllers (PLCs), robotic systems, enterprise resource planning (ERP) platforms, and cloud infrastructure. This level of integration enables manufacturers to automate and manage data across every stage of production with greater efficiency and control.

A key feature of these platforms is their no-code architecture, which allows manufacturers to develop highly accurate, domain-specific vision models without the need for programming expertise. By building on robust foundational models, users can quickly adapt systems to detect, inspect, or analyse product features tailored to specific use cases or production needs. This is the promise of AI machine vision.

Flexibility is central to the design of these platforms. Manufacturers can customise entire workflows to match the demands of their operations. This includes setting up vision systems for robotic arms or fixed cameras, managing stationary or free-moving products, adjusting AI models for different product variants, configuring trigger mechanisms, and defining output responses and integrations with wider business systems.

In addition, many modern platforms include built-in tools for creating custom dashboards and analytics. These features support tasks such as root cause analysis, process optimisation, and end-to-end traceability — all essential for maintaining quality and improving decision-making on the factory floor.

By offering such adaptability and ease of use, machine vision AI platforms are playing a growing role in modernising manufacturing, helping organisations boost productivity, enhance product quality, and stay competitive in an increasingly data-driven industry.

Conclusion

Machine vision has journeyed from a theoretical curiosity within AI to an indispensable technology across modern industry. Its evolution has mirrored, and often driven, developments in computing, optics, and artificial intelligence.

From the 1940s AI labs to 2025’s edge-intelligent robotic systems, machine vision has constantly adapted to meet the growing demands of efficiency, precision, and intelligence. The next frontier may include general-purpose visual intelligence, capable of operating across dynamic, unstructured environments—ushering in truly adaptable visual machines.

As we look ahead, the convergence of quantum computing, neuromorphic processors, and further AI integration promises to keep machine vision at the forefront of technological innovation.