In the highly regulated world of medical device manufacturing, every aspect of production must meet stringent quality control standards. One critical area is the packaging of devices, particularly in the form of blister packs and blister strips. Blister packs are commonly used for tablets, test strips, and other small medical components, while blister strips are typically used in inhaler-based products, where they serve as precision dosage systems for powder-based medications. In both formats, ensuring the integrity, accuracy, and traceability of the packaging is essential, not just for product quality, but for patient safety.

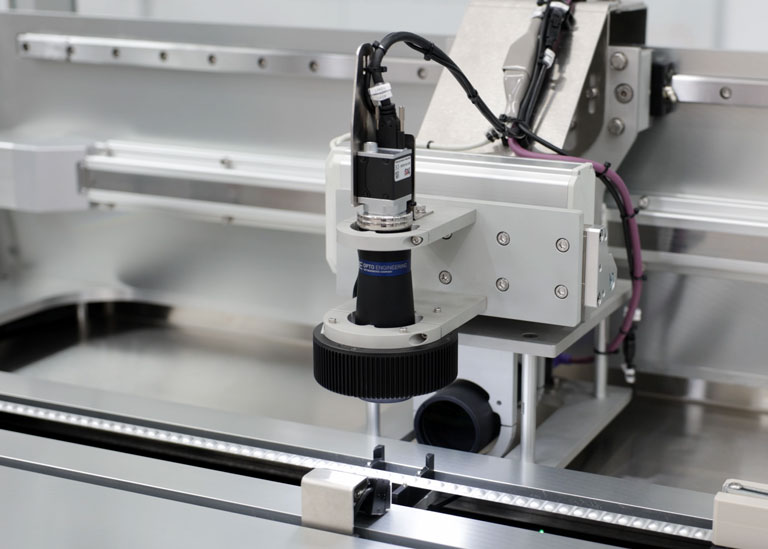

This is where machine vision systems play a vital role. Inspection powered by advanced vision technology ensures consistency, reduces human error, and maintains regulatory compliance.

Furthermore, aligning such systems with GAMP (Good Automated Manufacturing Practice) validation principles guarantees that vision systems are implemented, validated, and maintained in a way that meets both regulatory and operational expectations.

Let’s explore why vision systems are used for medical device blister pack and blister strip inspection, how they work, and how GAMP validation supports their reliable deployment.

What Are Medical Device Blister Packs and Why Inspect Them?

Blister packs are thermoformed plastic packaging sealed with a backing of aluminium or paperboard. In the pharmaceutical and medical device industries, they are used to hold individual units—be they tablets, test strips, or surgical staples—securely in compartments. Blister strips, often configured in a continuous or semi-continuous format, are used in dry powder inhalers or similar drug delivery systems. These strips must be accurately formed and dimensioned to function correctly in their respective medical devices.

Inspection of these packages ensures that: – All cavities are correctly filled – Products are in the correct orientation – Foreign objects or contaminants are absent – Seals are intact and properly aligned – Labeling and print (e.g., expiry dates, lot numbers) is clear and accurate – Blister dimensions are within tolerance for mechanical compatibility

Manual inspection is time-consuming, prone to errors, and difficult to scale. As a result, machine vision has become the preferred method for high-speed, high-accuracy inspection.

Why Use Vision Systems for Inspection?

Machine vision systems use cameras, lighting, and software algorithms to “see” and analyse what’s happening on the packaging line. They are capable of:

- High-Speed Inspection

Vision systems can inspect thousands of units per minute—far beyond human capability—while maintaining high levels of accuracy. -

Non-Contact and Non-Invasive Analysis

Vision systems inspect blister packs and strips without physically touching them, ensuring sterile or delicate products are not compromised. -

Consistent and Objective Judgments

Vision systems apply the same criteria to every unit, eliminating subjective decision-making and operator fatigue. -

Comprehensive Data Logging

Every inspection event can be logged for traceability and compliance. This data is critical for audits and root-cause analysis. -

Immediate Feedback and Integration

Vision systems can trigger alarms, remove faulty products from the production line, or adjust machine settings in real-time.

Typical Machine Vision Inspection Tasks in Blister Packs and Strips

Vision systems can be deployed at various stages of the packaging process. Typical inspection functions include:

- Presence/Absence Verification

Ensuring that each cavity contains a product and that no multiple fillings have occurred. -

Shape and Size Detection

Confirming that the product in the blister matches the expected shape and size. -

Color and Contrast Analysis

Detecting colour-coded items or ensuring that items have not been discoloured due to defects. -

Print Inspection

Verifying legibility and accuracy of lot codes, barcodes, and expiration dates using OCR (optical character recognition). -

Seal Integrity Checks

Detecting misaligned or incomplete sealing between the blister and backing. -

Foreign Object Detection

Identifying any unexpected items in the blister pack that could indicate a contamination event. -

Blister Form and Dimension Verification

Using metrology tools within vision systems to confirm that blister cavities are correctly formed. Accurate cavity depth, shape, and spacing ensure the strip will fit and move properly within a corresponding medical device.

How Machine Vision Systems Inspect Blister Strips

Blister strip inspection involves a sequence of highly specialized tasks that go beyond mere presence detection. These systems typically consist of multiple inspection stations, each optimized for specific checks:

-

Form Verification (Metrology Checks)

Before filling, blister cavities are inspected for correct shape and dimensions. This involves topographical imaging or laser triangulation to measure cavity depth, width, wall thickness, and pitch. Accurate forming is crucial as these strips often interface with automated drug delivery systems or diagnostic readers. -

Fill Verification

After forming, vision systems check that the correct item is placed in each cavity. 2D or 3D imaging confirms the product presence, orientation, and fit. Deep learning algorithms may be used to classify subtle shape variants or defects. -

Sealing Validation

During the sealing phase, systems use reflective or infrared lighting to detect sealing anomalies like wrinkles, bubbles, or partial seals that could affect sterility. -

Print and Label Verification

After sealing, vision modules check for correct label placement, print alignment, and clarity. OCR ensures that the printed information is correct and legible. - Dimensional Strip Measurement

Blister strips must often fit into tightly toleranced mechanical guides. Vision systems use calibrated optics to measure total length, width, and cavity spacing with micron-level precision. -

Reject and Sort Mechanism

Any detected non-conformance leads to automatic rejection using air jets or servo-driven diverters. Faulty items are collected and optionally imaged again for defect classification and process improvement.

Through this tightly integrated process, vision systems ensure not just product quality but functional compatibility with downstream devices.

GAMP and Validation of Vision Systems

Using a vision system in a regulated environment requires careful validation. GAMP 5 (Good Automated Manufacturing Practice) provides a structured approach for validating automated systems used in GxP (Good Practice) environments, including medical device manufacturing.

Key GAMP Principles Relevant to Vision Systems

-

Risk-Based Approach

GAMP promotes focusing validation efforts based on system complexity and risk to patient safety. A vision system used for final product inspection clearly ranks high in risk and must be rigorously validated. -

Lifecycle Approach

Validation isn’t a one-time task—it spans the entire lifecycle of the system, from user requirements to system retirement. -

Documentation Standards

GAMP requires traceable documentation of:- User Requirements Specification (URS)

- Functional Specification (FS)

- Design Specification (DS)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

-

Supplier Involvement

Since third-party vendors supply many vision systems, GAMP emphasises assessing supplier quality and leveraging vendor documentation and testing when appropriate. -

Change Control and Maintenance

Any updates to vision software or configuration must follow strict change control procedures, with revalidation as needed.

GAMP Category for Vision Systems

Vision systems typically fall under GAMP Category 4 or 5, depending on customization: – Category 4: Configured software, where standard vision platforms are tailored via scripting or parameter setting. – Category 5: Custom software, often involving bespoke algorithms or AI that cannot be validated using standard test cases.

Understanding the category helps define the depth of validation required.

Best Practices for Vision System Validation and Deployment

-

Early URS Definition

Clearly define what the system should do—detection thresholds, false reject limits, image retention requirements, etc. -

Vendor Selection

Choose vendors with experience in medical-grade vision systems and established quality management systems (QMS). -

FAT and SAT Testing

Perform Factory Acceptance Testing (FAT) at the vendor’s site and Site Acceptance Testing (SAT) upon installation to confirm functionality. -

Simulated Defect Testing

Use known-good and known-defect packs to test system sensitivity and false positive/negative rates. -

Audit Trails and Access Control

Ensure systems log user activity and image data. Role-based access should prevent unauthorised changes. -

Periodic Review

Implement a schedule for system health checks, calibration, and revalidation where necessary.

Conclusion

Vision systems have become indispensable in the inspection of medical device blister packs and blister strips, providing fast, accurate, and scalable quality control that meets the high standards of healthcare manufacturing. For blister strips in particular—used in powder-based inhalers—precision is critical, as any dimensional or content error could impair the device’s ability to deliver the correct dosage. The role of vision systems extends beyond quality assurance to ensuring that these strips interact properly with mechanical systems in drug delivery devices.

However, deploying these systems isn’t just a technical decision—it’s a regulatory commitment. Aligning implementation with GAMP validation principles ensures that vision systems operate reliably, remain compliant, and deliver measurable value throughout their lifecycle.

As technology continues to evolve, vision systems will only grow more capable, intelligent, and integral to the manufacturing process. For organisations that prioritise safety, efficiency, and compliance, investing in a validated vision inspection system is not optional—it’s essential.