A new video on the IndustrialVision YouTube channel showcases a special purpose vision machine for the inspection of a complex aerospace sub-assembly. Quality and reliability are essential, and so automated visual inspection is crucial to the manufacturing process. This machine was designed as a final end of line inspection machine to confirm product quality before it is shipped to the customer.

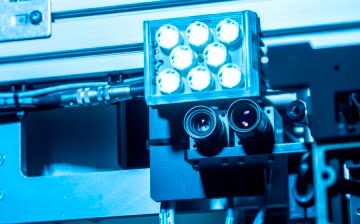

IVS created a special purpose inspection machine utilising five digital Gigabit Ethernet cameras and one pan, tilt and zoom camera. Lighting is an integral part of the system, using high intensity white LEDs combined with red laser line projections. IVS machine vision software contains a wide range of standard inspection functions, making it applicable to any industry. The software determines that the complete sub-assembly is manufactured correctly looking for machined surfaces, inserts, labels, screws and helicoills.

The aerospace customer can be assured that what they are supplying to their customer is of the highest quality and reliability. In addition they have historical photos and data supplied from the machine for every product leaving their factory for future traceability.

The video can be viewed at: http://youtu.be/9RGBTXR-h6A