June 2014. IVS have built a new machine for a major Tier 1 manufacturer of automotive components.

The build of an automotive handle comprises of many differing production processes including pressure die casting, injection moulding, painting and assembly of the final unit. All of these processes require careful planning to achieve the quality levels expected of a Tier 1 automotive supplier. The final inspection of the assembled unit and kit of handles which make up a complete car is critical prior to the product leaving the factory.

Because of this, the large UK-based OEM manufacturer of automotive door handles approached IVS to automate the process for inspection of these parts. The manufacturer produces an average of 100,000 keys or ID-devices, 60,000 door handles and 24,000 steering column locks each day and the quality of the products manufactured is critical to their success.

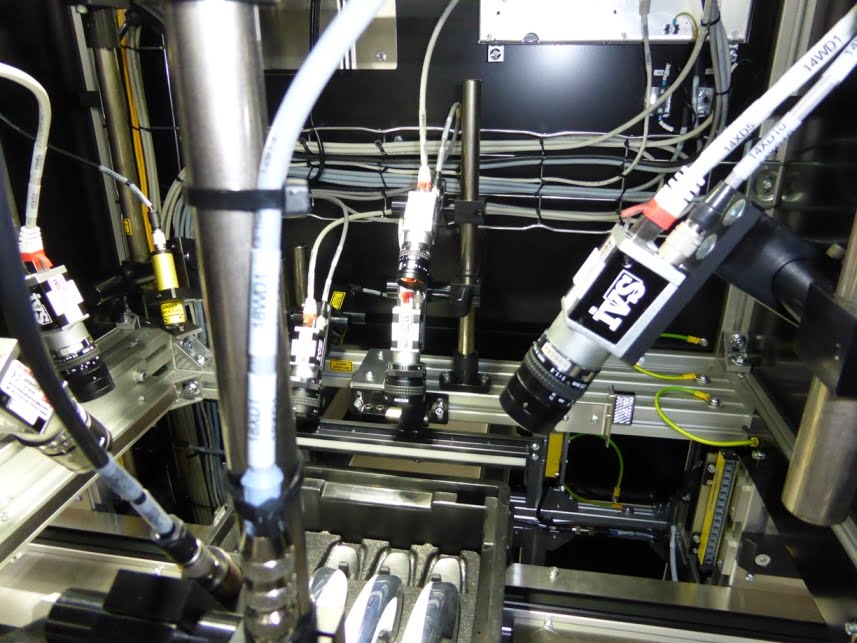

The manufacturer required a machine to perform a number of inspection tasks as part of the final automatic quality control of the product.

The complete case study can be found here.

A video of the machine in action can be found on our YouTube channel.