This month, we’re following on from last month’s post.

We’ve all seen films showing the dystopian factory landscape a few hundred years in the future. Flying cars against a grey backdrop of industrial scenery. Robots serving customers at a fictitious future bar, and probably – if they showed a production line, it would be full of automatons and robots. We will drill down on the role that industrial vision systems can have on the real factory production line. Is it the case that in the future, all production processes will be replaced with automated assembly, coupled with real-time quality inspection? Intelligent robots which can handle every production process?

Let’s start with what’s happening now, today. It’s certainly the case that machine vision has developed rapidly over the last thirty years. We’ve gone from slow scientific image processing on a 386 computer (look it up!) to AI deep learning running at hundreds of frames per second to allow the real-time computation and assessment of an image in computer vision. But this doesn’t mean that every process has (or can be) replaced with industrial vision systems, but what’s stopping it from being so?

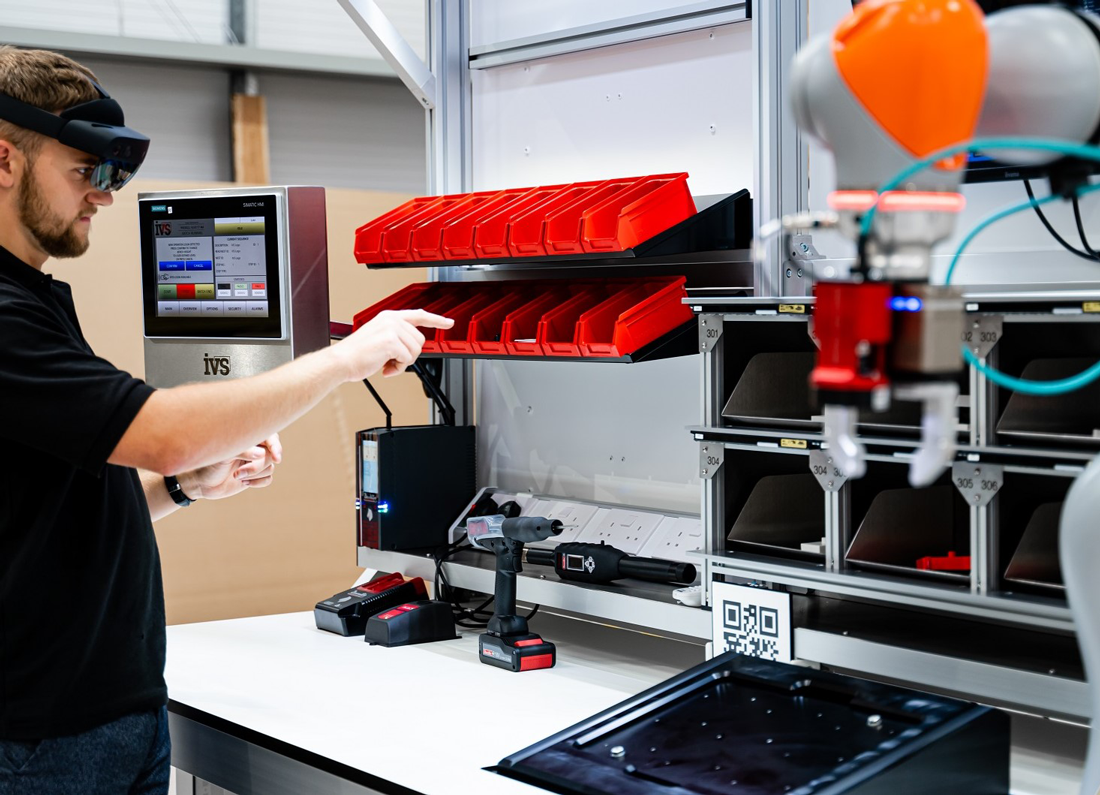

Well, the main barrier to this is the replication of the human dexterity and ability to manoeuvre the product in delicate (compared to an industrial automated process) ways. In tandem with this is the ability for a human to immediately switch to a different product mix, size and type of product. So you could have a human operator construct a simple bearing in a matter of seconds, inspect it – and then ask them to build next a completely different product, such as a small medical device. With some training and show how, this information exchange can be done and the human operator adapts immediately. But a robot would struggle. Not to say it couldn’t be done, but with today’s technology, it takes effort. This is the goal of Industry 5.0, the next step generation from Industry 4.0 flexible manufacturing. Industry 5.0 is a human-centric approach, so industry understanding that humans working in tandem with robotics, vision, and automation is the best approach.

So we need to look at industrial vision in the context of not just whether the image processing can be completed (be it with traditional algorithms or AI deep learning), but also how we can present the product meaningfully at the correct angles to assess it. Usually, these vision inspection checks are part and parcel with an assembly operation, which requires specific handling and movement (which a human is good at). This is the reason most adoption of machine vision happens on high throughput, low variation manufacturing lines – such as large-scale medical device production where the same product is validated and will be manufactured in the same way over many years. This makes sense – the payback is there and automation can be applied for assembly and inspection in one.

But what are the drivers for replacing people on production lines with automated vision inspection?

If the task can be done with automation and vision inspection, it makes sense to do it. Vision inspection is highly accurate, works at speed and is easy to maintain. Then there are the comparisons comparing the processes to a human operator. Vision systems don’t take breaks, don’t get tired, and robots don’t go to parties (I’ve never seen a robot at a party) – so they don’t start work in the morning with their minds not on the task at hand! So, it makes sense to move towards automated machine vision inspection wherever possible in a production process, and this represents huge growth in the adoption of industrial vision systems in the coming years.

If the job is highly complex in terms of intricate build, with many parts and variants, then robots, automation and vision systems are not so easy to deploy. However, with the promise of Industry 5.0, we have the template of the future – moving towards an appreciation of including the human operator in factory automation – combining humans with robots, automation, augmented reality, AI and automated inspection. So, the dystopian future might not be as bad as the filmmakers make out, with human operators still being an integral part of the production process.