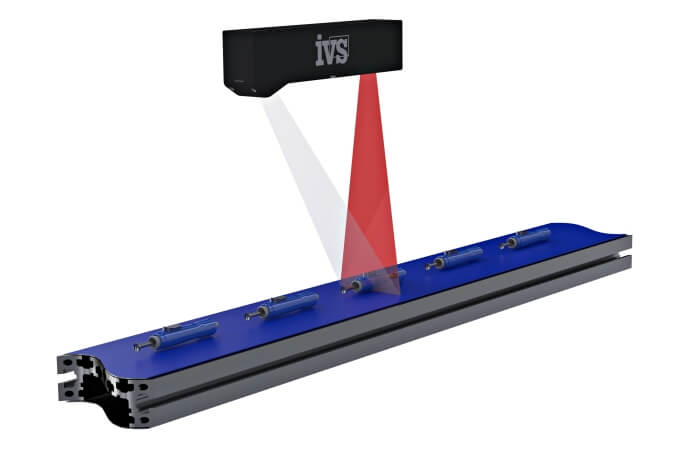

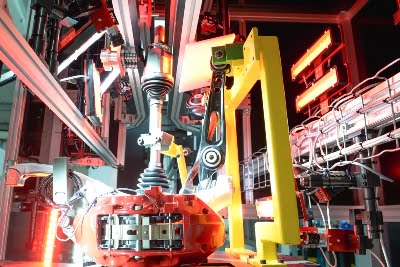

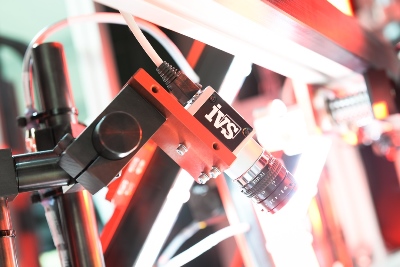

The next-generation IVS-NCGi range of digital cameras from Industrial Vision Systems provides a breakthrough in flexibility, performance and ease of use for machine vision inspection. With heightened resolution options for more precision and faster frame rates, the cameras are designed for integration into modern product processes. Its compact form factor easily fits into space constrained manufacturing lines and cells.

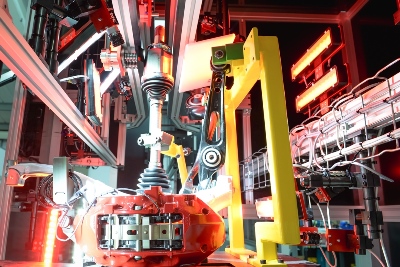

With manufacturers relying on dependable and consistent machine vision throughout the production process, these advanced camera heads provide industrial grade inspection capability with much higher resolutions allowing them to handle the most complex inspection and quality control tasks. Full integration with the IVS software platforms make it one of the most flexible vision systems on the market today.

The cameras come ready to be mounted with standard LED lighting options plus a wide range of field-changeable C-mount lenses and industrial autofocus lens options. The powerful IVS software platforms allow simple set-up and quick integration for inspection across all industry sectors. The cameras are ideally suited for presence verification, gauging, surface inspection and optical character recognition. In addition, the cameras fit the standard IVS-SVP IP65 rated housing for integration into food and harsh manufacturing environments.

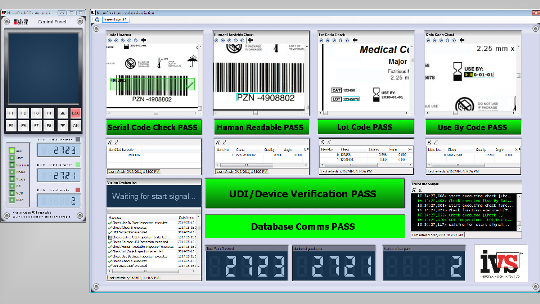

The IVS-NCGi cameras offer comprehensive and real-time communication between the cameras and factory information systems. IVS vision systems are designed to communicate with all PLCs, master controllers and proprietary factory controls out of the box allowing rapid integration and easy commissioning on the production floor. They offer fast and efficient operation at every stage from image capture to data output.

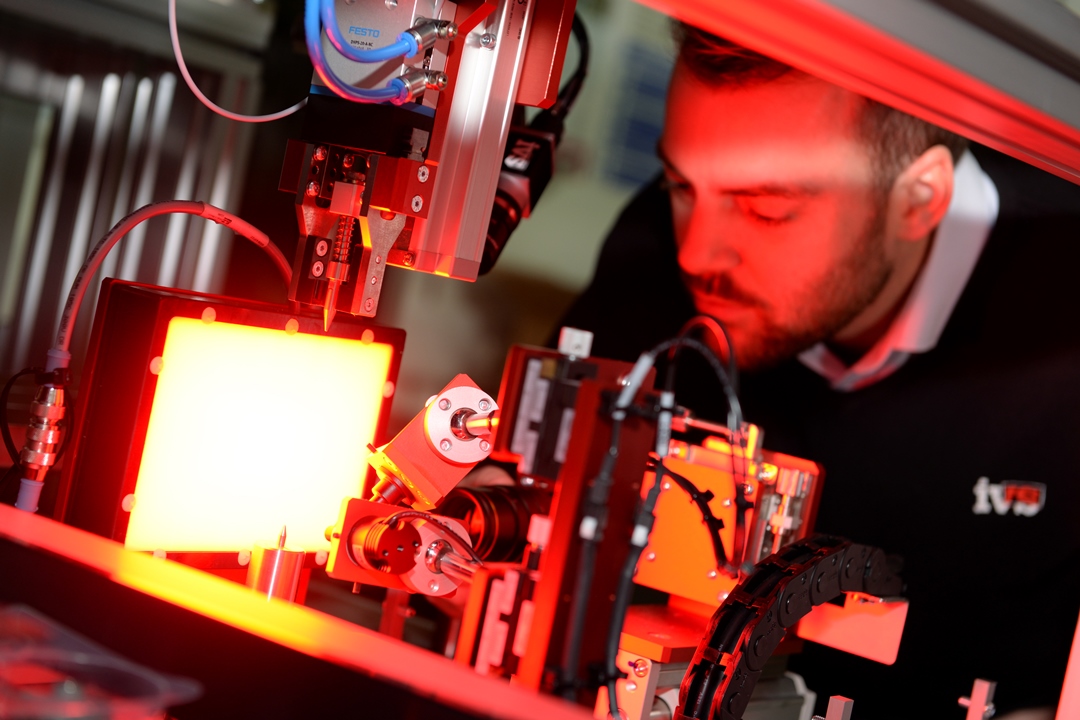

In terms of accessibility, the front of the enclosure cover can be easily removed to provide the user with full access to the vision system camera and optics, allowing changes to the focus and aperture settings.

In terms of accessibility, the front of the enclosure cover can be easily removed to provide the user with full access to the vision system camera and optics, allowing changes to the focus and aperture settings.

IVS vision camera systems can be configured and deployed with ease thanks to plug and play support within the industry standard NeuroCheck® software suite. These latest generation machine vision cameras provide state-of-the-art digital technology, offering precise signal processing and superior image quality.

IVS vision camera systems can be configured and deployed with ease thanks to plug and play support within the industry standard NeuroCheck® software suite. These latest generation machine vision cameras provide state-of-the-art digital technology, offering precise signal processing and superior image quality.