IVS continues to spearhead the automation revolution supplying some of the world’s leading brands with machine vision technology.

Oxford, United Kingdom, March 1, 2020 – Industrial Vision Systems (IVS®) is celebrating its 20th anniversary as a leading global machine vision provider. Founded in 2000, IVS has since grown to now serve customers around the world, with the supply of thousands of vision systems over their impressive 20-year growth.

“We’re very proud to see what IVS has become,” said Earl Yardley, Director, one of the co-founders of IVS. “We started IVS by mastering our clients’ production and quality control challenges. Reflecting on the continuing success we’ve had, it’s a reminder that we are still on the right path, particularly with the growth of machine vision, and the advent of deep learning and artificial intelligence in vision system deployment.”

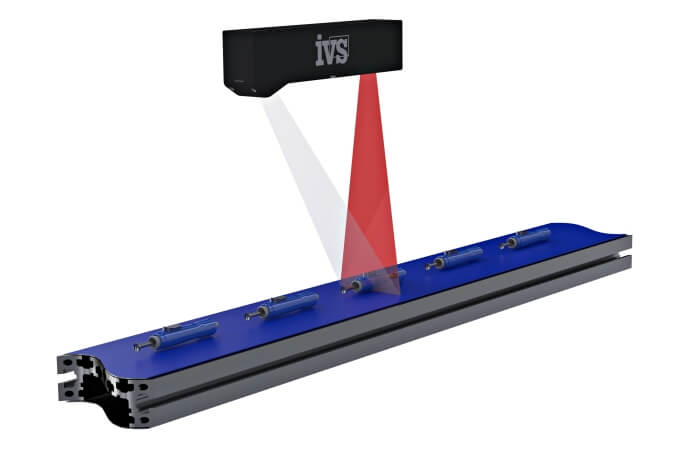

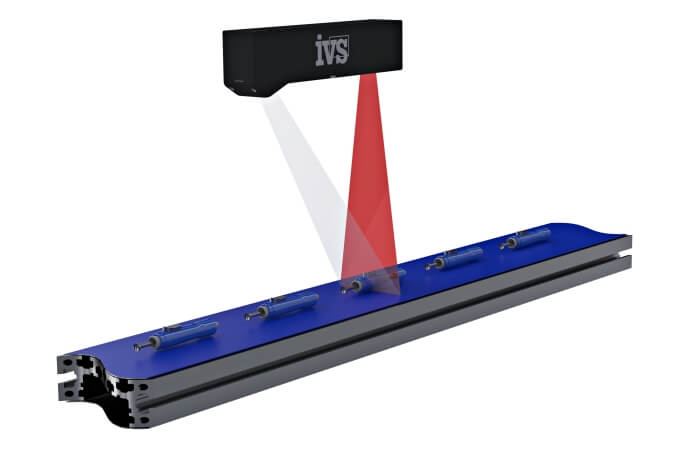

With proficiency in machine vision, robotics and industrial automation, IVS has developed a comprehensive suite of standard vision inspection machines, combined with hundreds of unique solutions to service major industries such as medical device, pharma, automotive, electronics and packaging.

IVS’s impressive growth can also be credited to the rise of machine vision and automation within production processes. Through standalone projects and complete automation lines, IVS’s global team has demonstrated its indisputable capability to support their customers at every step of the project process.

Andrew Waller, Director and co-founder, added: “IVS has an outstanding engineering team, who together address some of the most demanding and complex machine vision applications. Our team’s enthusiasm to understand and be tested by our customer problems has kept us focussed on being innovative, to ultimately further develop the company so that we can rise to any challenge over the next twenty years. We want to thank all our customers and employees for their trust and commitment which has made IVS one of the most respected machine vision suppliers to industry today.”

Launched in 2000, IVS vision systems are used all over the world in automated production processes for inspection, guidance, identification, measurement, tracking and counting. Its systems are reputed to be some of the most innovative and advanced machine vision solutions on the market today, successfully deployed in thousands of systems around the world.