Industrial Vision Systems (IVS) have relocated into a new facility – custom designed to its own specification – in order to fulfil its ambitious expansion plans. Having grown significantly over the course of the past sixteen years, Industrial Vision Systems has now made the move to its brand new 10,000 sq ft premises at the prestigious Harwell Science and Innovation Campus in Oxfordshire which will allow it to grow further and capitalise on new, emerging markets.

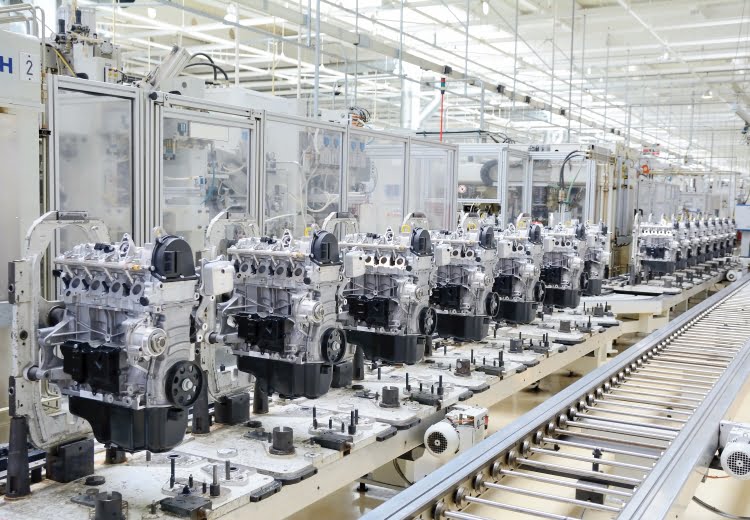

The relocation presents a new phase of business for IVS. The company is fully expecting year on year double digit growth in machine vision and robotics on the manufacturing floor over the next decade. The company has identified that Industry 4.0, flexible manufacturing and replacing unskilled labour are all key drivers in this expanding industrial sector. Therefore, IVS finds itself in the perfect position to capitalise on these emerging markets with a solid business foundation, high engineering expertise, and now increased engineering resource for the anticipated high demand.

The Harwell Science and Innovation Campus (www.harwellcampus.com) is one of the most advanced and active innovation communities in Europe, located just South of Oxford and only forty-five minutes from Heathrow Airport. IVS finds itself in good company, located close to the European Space Agency, Diamond Light Source and RAL Space, the overall campus hosts an array of over £1 billion of world leading research infrastructure. At the core of Harwell is collaboration. Its occupants and visitors have access to world-class engineering and scientific facilities, leading-edge research and an exceptional talent pool.

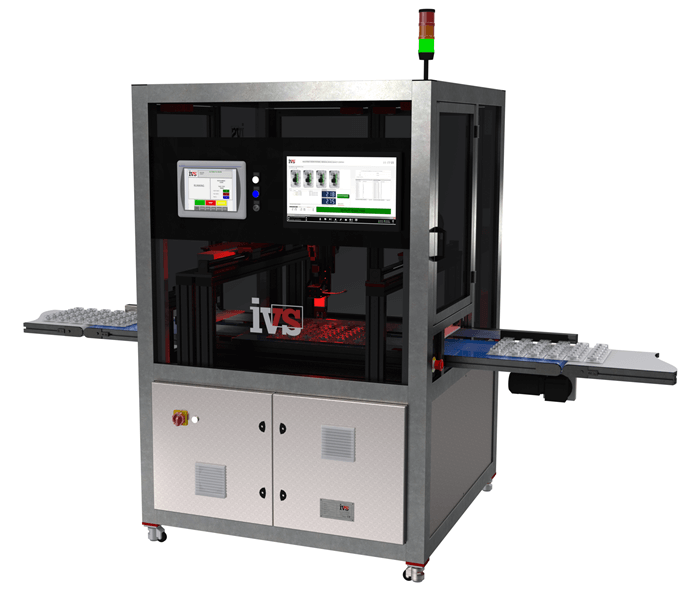

The new IVS facility features state of the art engineering offices, research and development areas, dedicated sales office and training rooms in addition to the production floor, breakout areas and administration. IVS has also invested in new demonstration equipment including collaborative robots, automated inspection test rigs and vision inspection machinery demonstrations, all of which will be available to view in the company’s new demonstration facility.

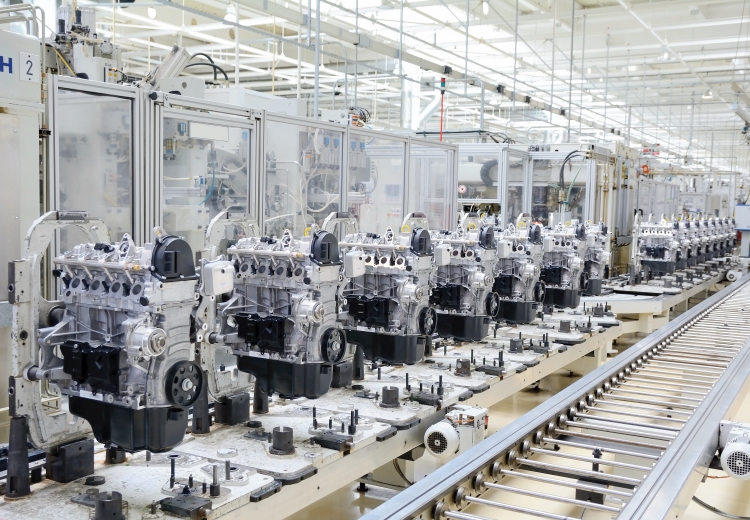

Industrial Vision Systems is also expanding into the supply of dedicated inspection machines in the key vertical markets it represents such as automotive, medical devices, electronics, food and packaging. These new machines have been designed for high levels automated visual inspection to enhance quality control. The growth and investment in this area will happen in tandem with the company’s traditional machine vision system supply and integration.

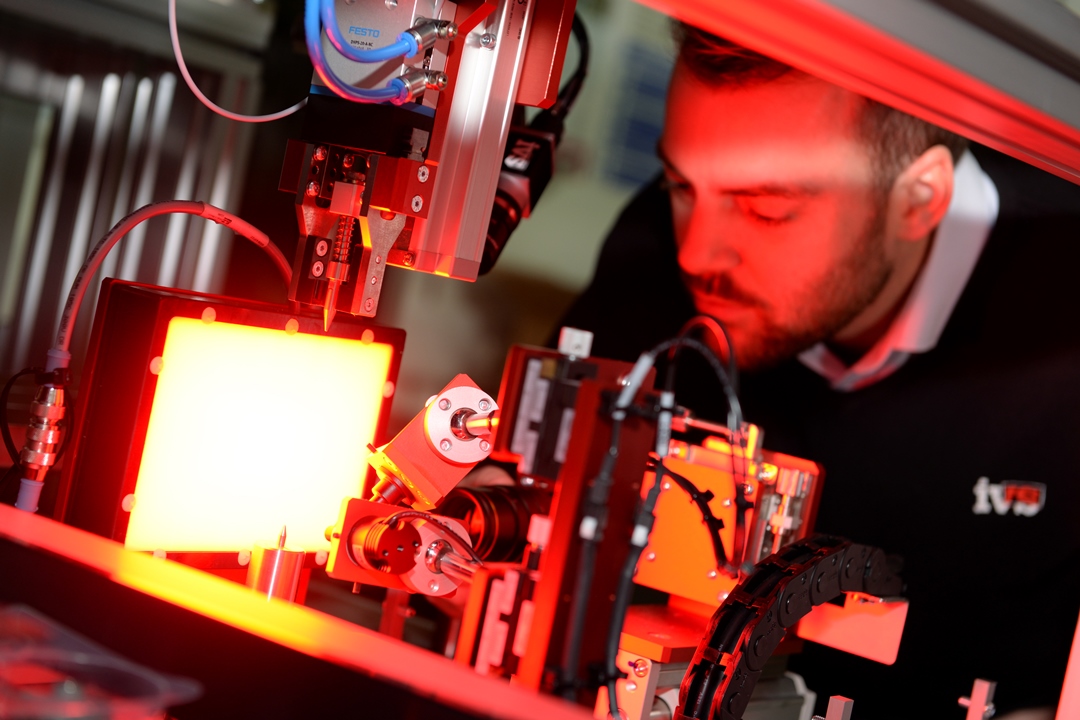

In terms of accessibility, the front of the enclosure cover can be easily removed to provide the user with full access to the vision system camera and optics, allowing changes to the focus and aperture settings.

In terms of accessibility, the front of the enclosure cover can be easily removed to provide the user with full access to the vision system camera and optics, allowing changes to the focus and aperture settings.