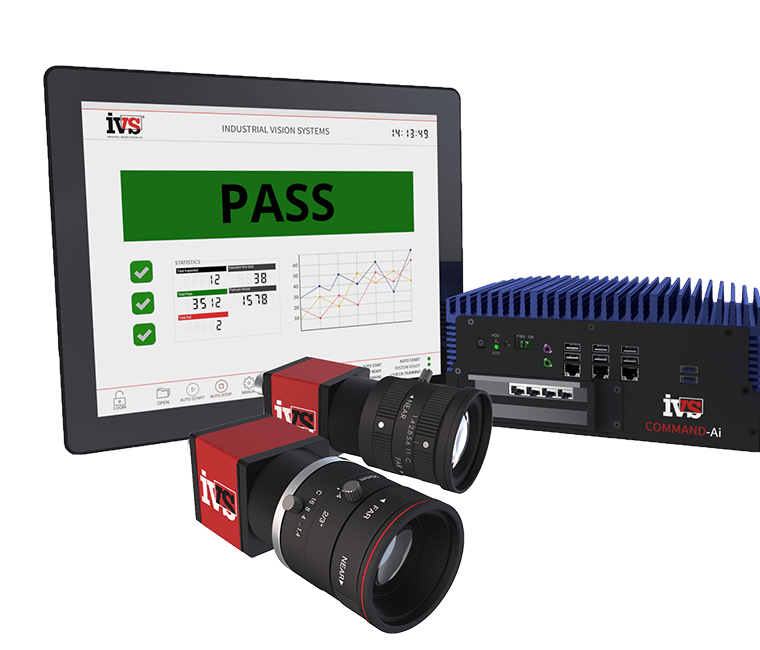

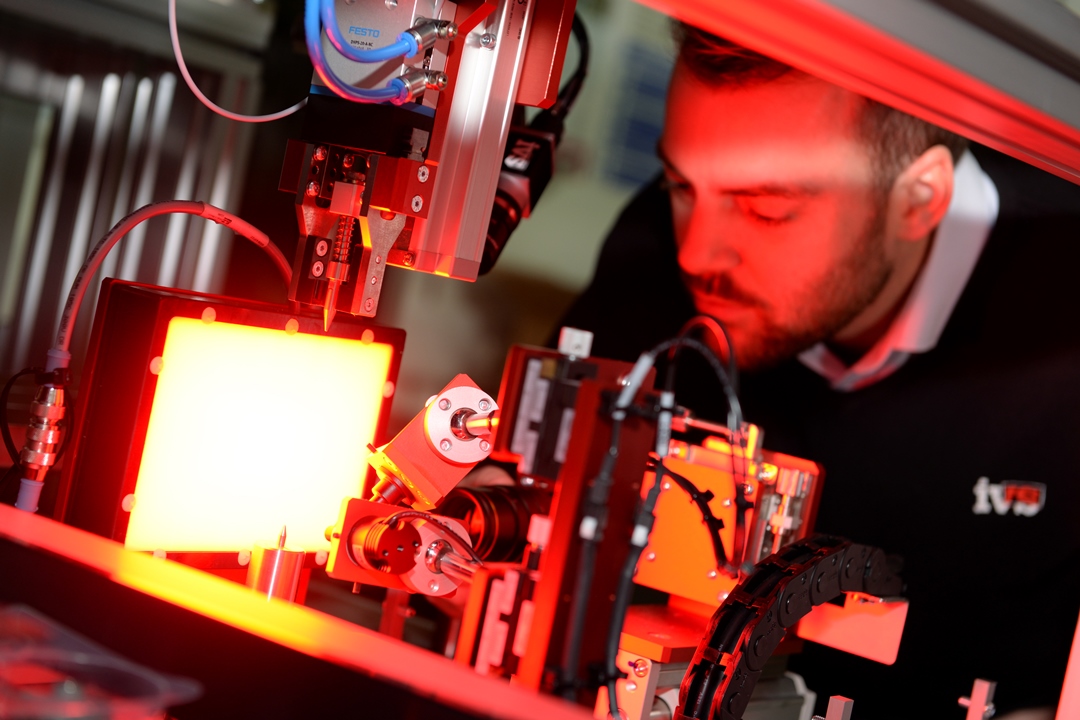

Industrial Vision Systems (IVS®), a supplier of machine vision systems to industry, has launched the IVS-COMMAND-Ai™ in-line inspection solution designed for high-speed automated visual inspection, helping reduce manufacturer fines and protecting brand reputations. The IVS-COMMAND-Ai Vision Sensors integrate directly with all factory information and control systems, allowing complete part inspection, guidance, tracking and traceability with additional built-in image and data saving.

For those applications requiring complex classification, the IVS-COMMAND-Ai system utilises the latest deep learning artificial intelligence (ai) vision inspection algorithms. New multi-layered “bio-inspired” deep neural networks allow the latest IVS® machine vision solutions to mimic the human brain activity in learning a task, thus allowing vision systems to recognise images, perceive trends and understand subtle changes in images which represent defects.

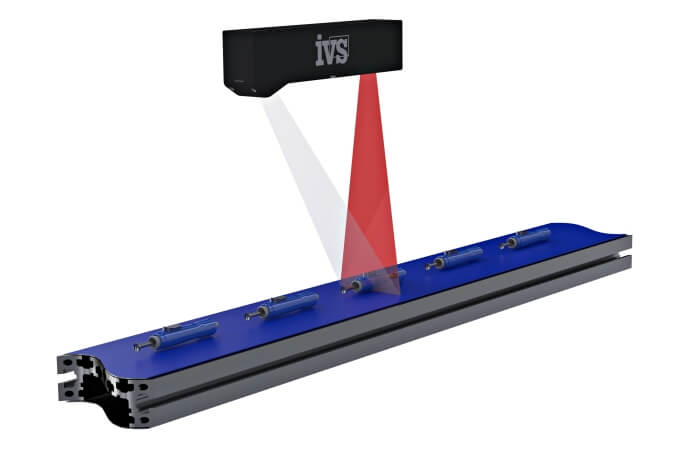

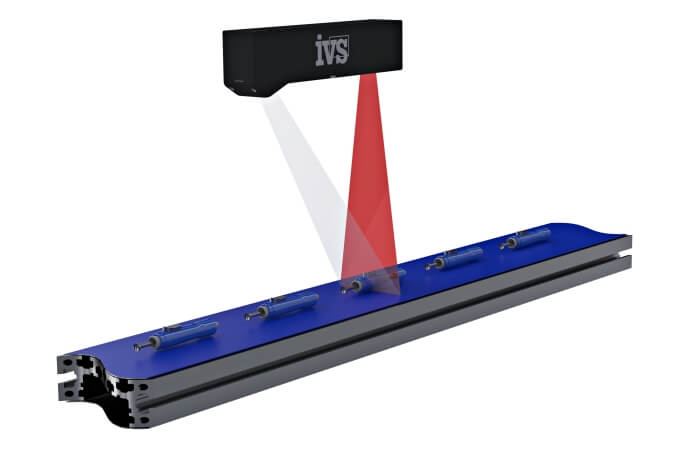

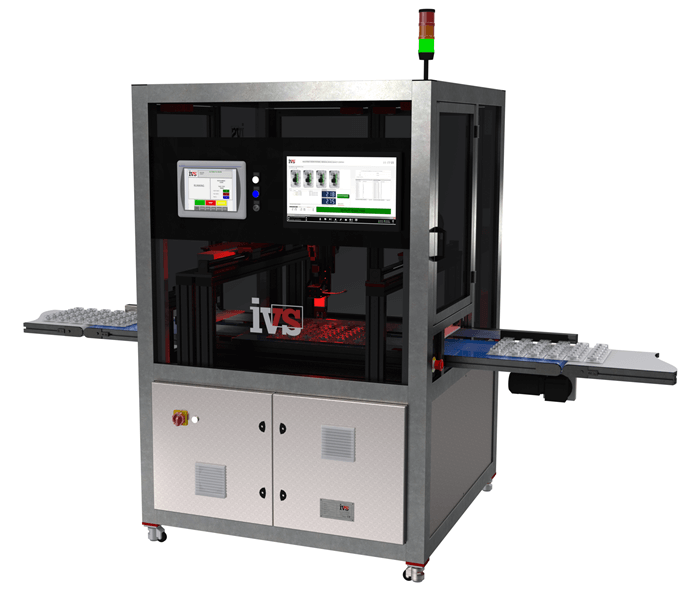

Designed for complex manufacturing industries such as medical devices, pharmaceuticals, food & drink and automotive, the IVS-COMMAND-Ai Vision Systems are fitted with adaptable HD smart cameras to provide inspection from all angles and at high precision. This allows production lines to review and alert any flaws and defects in real-time, providing instant factory information on compatible devices. It also possesses speeds of up to 60 frames per second and can quickly be integrated on-line to inspect high speed and static products.

By achieving a robust inspection performance, the new IVS-COMMAND-Ai Vision Systems oversees complex vision inspections such as presence verification, OCR and gauging through to surface, defect and quality inspection in one solution. Comprehensive Statistical Process Control (SPC) data also provides closed-loop control to further safeguard production.

All IVS vision sensors can be integrated onto production lines, assembly cells, workbenches, robots and linear slides. Their robust design allows vision sensor integration into any industrial production process for seamless inspection, identification or guidance.

Earl Yardley, director at Industrial Vision Systems, comments: “Our vision systems are very easy to program, are highly accurate, offer easy maintenance and provide peace of mind in final quality acceptance. However, the IVS-COMMAND-Ai vision systems take it a step further. It is the complete, robust quality control inspection vision sensor solution, and it is ready to be deployed in all manufacturing environments. It will improve yield and deliver immediate improvements to product quality; and at these critical times, reliability and consistency are vital.”

In terms of accessibility, the front of the enclosure cover can be easily removed to provide the user with full access to the vision system camera and optics, allowing changes to the focus and aperture settings.

In terms of accessibility, the front of the enclosure cover can be easily removed to provide the user with full access to the vision system camera and optics, allowing changes to the focus and aperture settings.